Smart Maintenance in Steel and Mining: Driving Reliability, Efficiency, and Sustainability

Introduction

Steel and mining are among the most asset-intensive industries globally. Steel plants rely on large blast furnaces, rolling mills, and coke ovens, while mining operations use fleets of crushers, conveyors, and haul trucks in remote and harsh terrains. The effectiveness, profits, and safety of these industries depend greatly on equipment reliability. However, both sectors have historically struggled with equipment failures, unplanned downtime, and rising maintenance costs.

To tackle these issues, companies are embracing Smart Maintenance, a modern approach that combines predictive maintenance (PdM), condition monitoring, the Industrial Internet of Things (IIoT), and Artificial Intelligence (AI). Unlike traditional maintenance, Smart Maintenance uses digital technologies to forecast failures, optimize maintenance schedules, and support real-time decision-making. This shift turns maintenance from a cost burden into a strategic advantage.

This article delves into Smart Maintenance in steel and mining. It looks at the evolution of maintenance practices, defines key principles of smart maintenance, highlights supporting technologies, discusses challenges and benefits specific to each sector, and offers a roadmap for implementation.

What is Smart Maintenance?

Smart Maintenance refers to a learning-oriented, self-regulated, and intelligent approach that maximizes both technical and economic effectiveness of maintenance by using digital technologies. It goes beyond just fixing equipment before it breaks. It seeks to change the entire maintenance culture within industrial organizations.

A crucial aspect is the move from human intuition to data-driven decision-making. Traditional maintenance often relies on technician experience and scheduled tasks. In contrast, Smart Maintenance introduces algorithms that offer highly accurate, though sometimes unclear, predictions. This creates tension between accuracy and transparency; while algorithms can surpass human reasoning in specific tasks, they frequently lack clarity, raising concerns about trust.

Leaders are essential in this transition. They need to establish trust in technology, guide workforce retraining, and manage the cultural shift that comes with Smart Maintenance. In a Smart Factory context, job roles change:

- Operators transition from manual tasks to managing exceptions in automated settings.

- Maintenance experts evolve from troubleshooters into overseers of predictive systems.

- Quality specialists move from routine inspections to smart engineering of processes with online

quality control.

Thus, Smart Maintenance signifies not only a technological change but also an organizational and cultural shift.

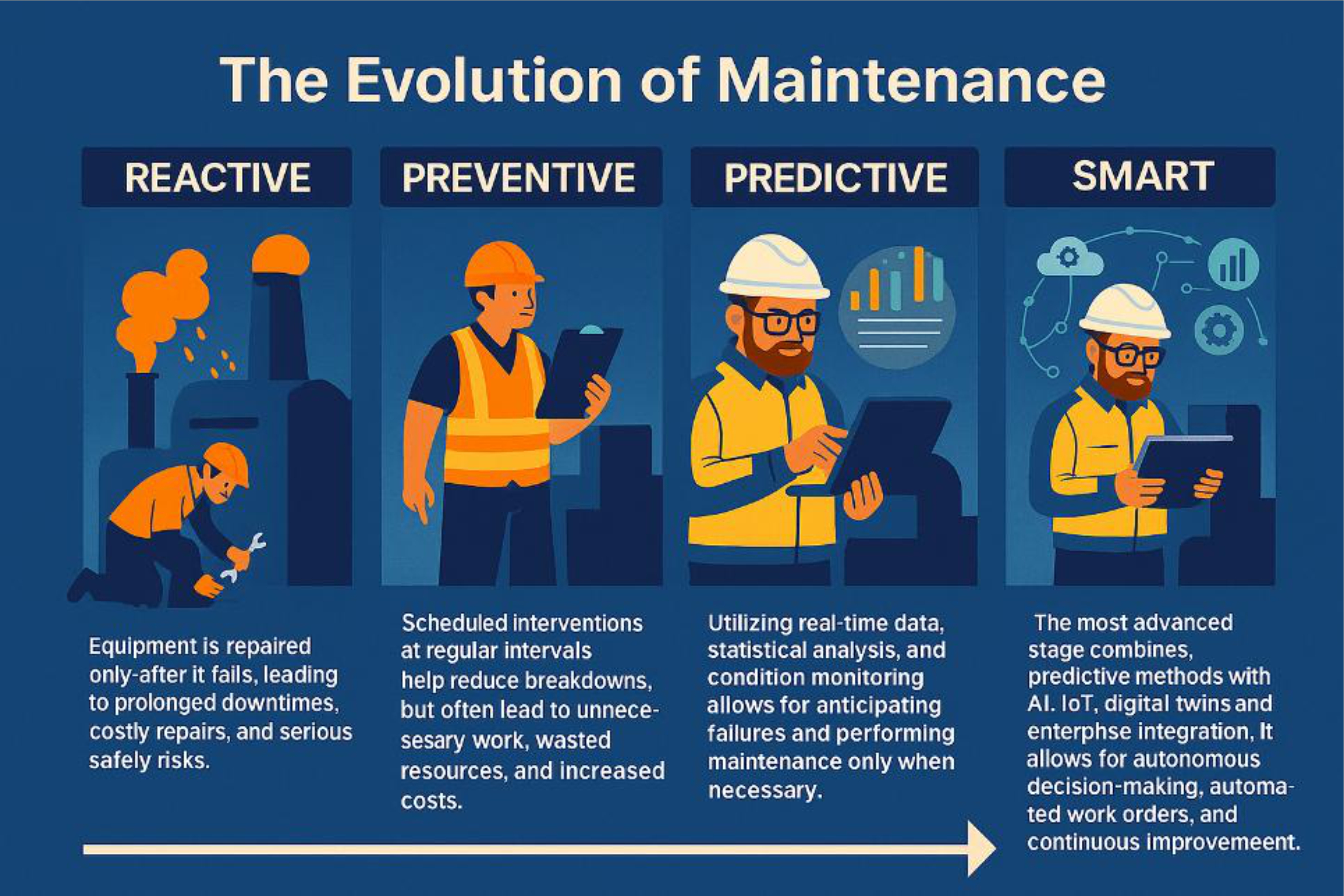

Evolution of Maintenance Strategies

Maintenance practices have evolved over decades in response to the growing complexity of industrial operations:

1. Reactive Maintenance (Breakdown) – Equipment is repaired only after it fails, leading to prolonged downtimes, costly repairs, and serious safety risks.

2. Preventive Maintenance (Time-Based) – Scheduled interventions at regular intervals help reduce breakdowns, but often lead to unnecessary work, wasted resources, and increased costs.

3. Predictive Maintenance (Data-Based) – Utilizing real-time data, statistical analysis, and condition monitoring allows for anticipating failures and performing maintenance only when necessary.

4. Smart Maintenance (Integrated, Intelligent) – The most advanced stage combines predictive methods with AI, IoT, digital twins, and enterprise integration. It allows for autonomous decision-making, automated work orders, and continuous improvement.

In steel and mining, the shift from preventive to smart maintenance is especially crucial. Downtime costs in these sectors can range from $10,000 to $3.5 million per hour, excluding the impact on supply chains and customer relations.

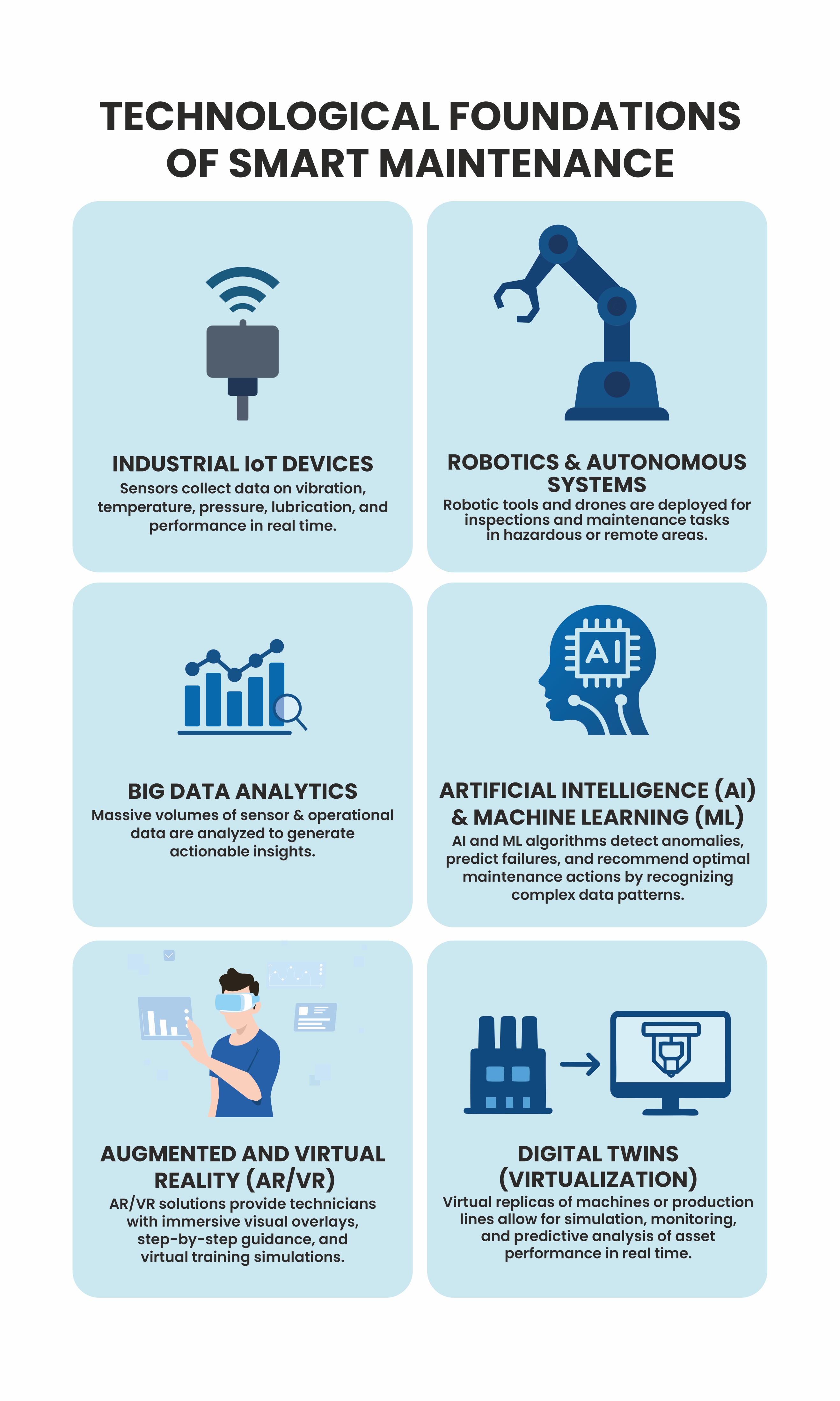

Technological Foundations of Smart Maintenance

Smart Maintenance relies on a combination of interconnected technologies and principles:

• Industrial IoT Devices: Sensors collect data on vibration, temperature, pressure, lubrication,

and performance in real time.

• Robotics and Autonomous Systems: These are used for inspections and tasks in dangerous or

remote areas.

• Big Data Analytics: Large amounts of sensor data are processed to derive actionable

insights.

• Artificial Intelligence (AI) & Machine Learning (ML): They detect anomalies, predict failures,

and optimize strategies through pattern recognition.

• Augmented and Virtual Reality (AR/VR): These tools assist technicians with visual overlays and

simulation training during maintenance.

• Digital Twins (Virtualization): Virtual replicas of machines or production lines allow for

simulation, monitoring, and predictive insights.

These technologies follow principles like modularity, interoperability, decentralization, service orientation, and real-time responsiveness. Together, they empower a factory or mine to adapt quickly to internal issues and external needs.

Smart Maintenance in the Steel Industry

The steel industry features continuous production processes, where even minor disruptions can halt entire operations. Key assets include blast furnaces, rolling mills, coke ovens, and material handling equipment.

Challenges in Steel Maintenance:

- Operating in harsh environments with extreme heat and vibration.

- Dealing with legacy systems that have poor digital integration.

- Managing high energy consumption and emissions that require improvement.

- Adapting to short product cycles and demand fluctuations that necessitate flexible operations.

Case Study – Tata Steel & Bosch Digital Twin:

Tata Steel implemented an IoT-enabled predictive framework across a vast number of assets, showcasing the scale of smart maintenance in steel.

Bosch collaborated with steel producers to install digital twins of coke-oven exhausters, allowing for predictive interventions and reducing unexpected breakdowns.

Benefits Observed:

- Reduced unplanned downtime.

- Lower maintenance costs.

- Energy optimization through better scheduling and control.

• Enhanced safety by minimizing manual work in dangerous environments.

Smart Maintenance in the Mining Industry

Mining presents unique challenges such as geographically spread operations, extreme conditions (dust, heat, vibrations), and a reliance on heavy mobile equipment. Critical equipment includes haul trucks, conveyors, crushers, and drilling rigs.

Challenges in Mining Maintenance:

- Remote operations create challenges in technician deployment.

- Harsh conditions increase wear and tear on equipment.

- Legacy ERP systems often lack the capacity for large amounts of data integration.

- Safety risks arise due to heavy machinery and hazardous work environments.

Case Study – Iron Mining Company with SAP S/4HANA:

A prominent mining company switched from legacy systems to SAP S/4HANA and integrated predictive maintenance with Reliability-Centered Maintenance (RCM). Outcomes included:

- 40% reduction in repair costs.

- 3% improvement in equipment reliability.

- Deployment of 20,000 maintenance strategies and 140,000 process maps.

- Use by over 1,000 users across multiple sites.

This case illustrates the significant impact of combining predictive analytics, risk prioritization, and ERP systems in mining operations.

Benefits Observed:

- Notable cost savings.

- Improved safety via proactive measures.

- Extended asset lifespan and utilization.

- Enhanced workforce efficiency and decreased travel for technicians.

Artificial Intelligence in Smart Maintenance

AI plays a central role in Smart Maintenance, providing various advantages:

- Learning from data: AI models can identify complex patterns in sensor information.

- Statistical predictions: AI delivers predictions with confidence levels, aiding in risk-based

decisions.

- Tolerance for uncertain data: Unlike rule-based systems, AI can manage noisy or incomplete

inputs.

Applications in Steel & Mining:

- Detecting anomalies in rolling mills, crushers, or turbines.

- Predicting failures in bearings, valves, and motors.

- Optimizing spare parts inventory and technician assignments.

- Using Natural Language Processing (NLP) for maintenance manuals and troubleshooting advice.

Benefits Demonstrated:

- A chemical manufacturer cut downtime by 80% and saved $300,000 per asset through

AI-based predictive maintenance for extruders.

- Boeing reduced wiring production time by 25% with AR/AI solutions, lowering error rates to nearly

zero.

- TEPCO (Japan) used AI-driven maintenance to halve substation visits and cut CO₂ emissions by 100 tons

annually.

Drawbacks and Challenges:

- Training AI models requires large data sets.

- Poor-quality historical records in older equipment can hinder efforts.

- IoT deployment costs can be high in distant locations.

- There is a risk of algorithmic bias leading to false alerts or overlooked failures.

- Continuous collaboration between the client and implementer is needed for effective alignment.

AI in maintenance should not be seen as a one-time fix. It requires ongoing refinement, management, and human supervision.

Implementation Roadmap for Smart Maintenance

Drawing from experiences in steel and mining, a structured roadmap can assist with implementation:

1. Identify Critical Assets – Prioritize equipment that significantly affects production, safety, or

costs.

2. Deploy IoT and Sensor Networks – Install sensors for vibration, temperature, lubrication, and

performance.

3. Collect and Integrate Data – Set up pipelines for real-time data ingestion, cleansing, and

storage.

4. Select AI/Analytics Tools – Develop predictive models for spotting anomalies and forecasting

failures.

5. Integrate with Enterprise Systems (ERP/CMMS) – Link predictive insights with work order systems for

smooth execution.

6. Develop Maintenance Strategies – Use Reliability-Centered Maintenance and Failure Modes and Effects

Analysis (FMEA).

7. Train Workforce – Provide technicians with AR/VR tools, AI dashboards, and digital skills

training.

8. Execute and Monitor – Enable automated alerts, remote monitoring, and robot-assisted tasks.

9. Continuous Improvement – Refine models based on feedback, Root Cause Analysis (RCA), and updated

data.

This step-by-step approach guarantees scalability, reduces resistance, and aligns technology with organizational needs.

Challenges and Barriers

Despite its potential, Smart Maintenance faces several obstacles:

- Insufficient technical knowledge of older assets.

- Tough working conditions (underwater, high-temperature, noisy environments).

- Geographic spread complicates remote workforce management.

- Slow spare parts supply chains may need additive manufacturing.

- Data challenges: incomplete, inconsistent, or low-quality records.

- Proven analytics gap: not every AI/ML model performs well in dynamic industrial environments.

- Cultural resistance exists, with some workers skeptical of algorithm trust and job displacement.

Addressing these issues requires investment in training, management, data quality, and phased adoption plans.

Strategic Benefits of Smart Maintenance

When implemented successfully, Smart Maintenance offers significant benefits:

- Reduced downtime – Predicting failures helps avoid costly breakdowns.

- Lower costs – Efficiency can lead to a 5-10% reduction in maintenance expenses.

- Improved reliability – Uptime may increase by 10-20%.

- Resource optimization – Better use of technicians, spare parts, and lubricants.

- Safety and sustainability – Reduced accident risks, lower fuel consumption, and fewer

emissions.

- Competitiveness – Faster market response, increased productivity, and enhanced customer

satisfaction.

Future Outlook

Smart Maintenance extends beyond steel and mining. It fits within a broader Industry 4.0 ecosystem, encompassing Smart Grids, Smart Mobility, Smart Logistics, and Smart Buildings. The combination of IoT, AI, robotics, and cloud platforms will generate fully integrated, self-optimizing industrial systems.

In steel and mining, the future may include:

- Autonomous mobile robots carrying out inspections.

- Fully digitized maintenance workflows supported by AR.

- Integration of sustainability metrics (energy, emissions) into maintenance performance indicators.

- Greater use of digital twins to simulate and enhance operations.

Ultimately, Smart Maintenance will redefine maintenance as a key driver of resilience, competitiveness, and sustainability.

Conclusion

Smart Maintenance represents a major shift in steel and mining. Moving from predictive and preventive strategies, it is now a vital necessity that integrates AI, IoT, digital twins, and reliability frameworks into daily operations. By minimizing downtime, optimizing resources, improving safety, and cutting expenses, Smart Maintenance helps steelmakers and miners transform challenges into opportunities.

Although challenges remain — including data quality, cultural resistance, and tough working conditions — the direction is clear: maintenance is evolving from merely reacting to failures to creating intelligent, adaptable, and sustainable operations. In industries where every minute of downtime can lead to significant losses, Smart Maintenance is more than just an innovation; it is foundational to future competitiveness.