Are you listening? Your Oil is screaming...

Have you ever observed, I repeat – OBSERVED, your Hydraulic System? Particularly your oil tank? If not,

check your machine. Observe it carefully from all sides. It is ‘the heart’ of your Hydraulic system. The

workhorse of your hydraulic system is stored there inside the oil tank. You will never be able to see

inside it but better you know what happens inside the oil tank when the machine is running.

In fact, a reservoir or oil tank is an oil torture chamber. Oil is flogged by all means inside the tank.

Many times it is screaming but you never listen to it and go on flogging it mercilessly. And one day

your workhorse becomes sick or dies altogether. Not only it but along with it, the majority of main

components like pumps and valves also give up. No one can say which one will die first, Oil or Pump or

Valve.

The root cause of the whole Hydraulic System failure is that no one listens to this workhorse screaming.

Remember oil is the main power behind the power of your machine. It is like what is blood for living

organisms. Oil will tell you everything about it. It will also let you know the status/condition of the

whole hydraulic system, do not ignore it.

What your oil is saying?

- Do not allow unqualified and inexperienced persons to manage the hydraulic system or oil. Chances are that they may damage the system and expensive components like the oil itself, pump & valve. Damage might increase manifold.

- Use reliable quality and genuine branded oil in seal-pack containers only. In the long run, the use of cheap oil is much more expensive than the original good-quality oil. Please note- cheap or duplicate oil will not have the required level of additives though it will look like clean oil.

- Please keep the oil tank painted from inside. The epoxy paint will be the best. If you are buying

the new system, ask the manufacturer to paint it with Epoxy paint only. It may be a little costlier

than a normal red oxide coat but in the long run, it will compensate for the cost.

Fig. 1 - Epoxy Painted Oil Tank

Fig – 2 - Red oxide coating of the Tank - The cost of stopping the contamination before entering into the system is cheaper than removing it. Get the new oil also filtered at the time of filling the tank.

- Do not change the entire quantity of oil without getting it tested. It is too expensive to change, rather you may be able to use the oil after proper filtration. Consult an Oil Expert.

- While changing the entire quantity of oil, clean the oil tank thoroughly from inside. Remove all sticky sludge, silt, and particles with the help of diesel/kerosene and wipe it clean and dry before filling it.

- Remember, the oil filtration exercise must be the last exercise. Complete all Hydraulic maintenance work before oil filtration and no more hydraulic maintenance work should be carried out after oil filtration and sealing the Oil tank.

- Get the oil filtered up to the required oil cleanliness level as per international standards like

NAS/ISO by an expert and know the oil cleanliness level before and after filtration. This is

possible only with Particle Count and not by Patch Test. The Patch Test method will not give you

accurate quantitative results.

Fig – 3 - Cleaned Oil Tank

- After filling the oil tank, seal it and do not allow oil or wet parts to get exposed to the environment.

- Get oil filtered at least once a year.

- Insist the tank fabricator to NOT keep top covers flushed with the tank top plate. Flushed covers are another source of water & dirt entering the oil tank in spite of the gasket/rubber seal. A slightly raised (5 to 10 mm) welded seat on the top plate for the cover will prevent water and dust from entering the oil tank directly.

- Suction strainer cleaning is not required if your oil is clean. As such you need not require cleaning it at all. Avoid taking it out for cleaning. In a way, suction strainers are not system-critical filters if you are filtering the oil regularly. They are used to prevent large particles like lint, plastic granules, metal chips, sometimes nuts and bolts, etc. from going to the pump. Though it is not advisable, in case you cannot avoid it, before dipping the hands in oil, wash it thoroughly with soap. Wash the strainer with diesel/kerosene and dry air pressure and refit it after washing your hands once again.

- Regularly clean the breather fitted on the top of the oil tank. It filters the air entering the

tank. Use a desiccant-type breather if you are located at a place where the air is too moist. It

filters the air as well as removes moisture from the air from entering into the tank. Power Pack

manufacturers normally use normal breathers to keep the cost low as it is cheaper but it will not

remove moisture.

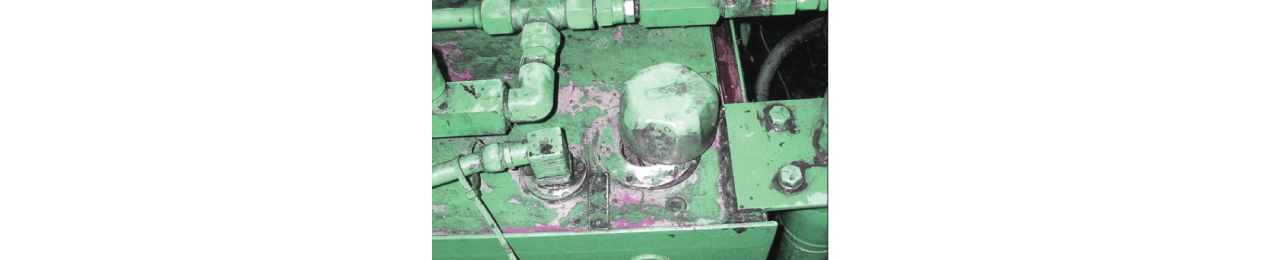

Fig – 10 - Regular Breathers

Fig – 11 - Desiccant Breather

Fig – 12 - Uncleaned and carelessly left open breather

- Seal all the tank openings. Most of the time oil tank fabricators leave big holes for inserting the pipes and the annular opening is left unsealed. This is the main and direct passage for contamination to enter the oil tank. Check the tank covers and seal any such openings. Ask the Power Pack supplier to take care of it in the first place itself.

- Regularly measure the water inlet and outlet temperature of the cooler. A normal temperature difference should be a minimum of 50 centigrade. If the temperature difference is low, clean the water cooler tubes. Avoid cleaning these water tubes which are made of copper, by a rod. Get it cleaned by professionals with chemical treatment. Rod may damage the soft copper tube and even if a hairline crack is developed, water will start mixing with oil.

- Dirty oil level indicator glass will tell you so many things about the condition of oil. Keep a watch on it regularly.

-

Check the oil level through the oil level indicator regularly and maintain the oil level within the

prescribed limit by topping it off with filtered oil. A low oil level will result in heating and a

high oil temperature leads to faster deterioration of the oil.

Fig – 7 - Level Guage -

Check the clogging indicators of the main system filters.

Fig – 8 - Clogging Indicator

If the filter element is chocked, it will be indicated by any form of a signal, either visual, or electrical on your PLC, or hooter. In case the oil looks to be dirty or you have not changed the filter element for a long time and the filter indicator is not giving the signal, chances are that the bypass valve fitted inside the head of the filter is opened or filter elements inside is broken and dirty oil is circulating into your system without you noticing it. Get the help of an expert if you are not able to identify the filter element fitted inside the filter. Replace it with the original one only or the equivalent of a similar reputed make. - If temperature and pressure indicators are fitted in the hydraulic circuit, check it regularly. Replace the faulty one immediately. In normal circumstances, the oil temperature should be around 500 centigrade only. Above 600 centigrade is a serious matter and consult the expert immediately.

- If you find any external leakage, consult the expert and replace the necessary seals. The system must work without any external leakage. There should not be a leakage of a single drop of oil from anywhere.

- Never ever pour the leaked oil back into the tank even if it is a large quantity, which may be due to the rapture of the hose. Store it in a separate clean drum preferably a plastic drum after cleaning it thoroughly from inside. Avoid using old metallic drums, chances are that they may be rusted and will make your relatively clean oil more dirty.

- Before reusing such leaked oil get it filtered professionally by the expert.

Most companies are taking bold steps to reduce their carbon footprint. Very little attention is given to the lubricants, they are often replaced early without thinking about the re-usage. When lubricants are monitored properly, it can be saved and reused which would lead to fewer oil changes. If the lubricants are changed based on their conditions and not because of the fixed intervals, the contribution to the betterment of the environment is done. Taking care of your oil is very important. The above-mentioned points might be the reason for oil contamination and why your oil is screaming. Listen to it and take care of it.