Emerging Markets for Synthetic Base Stocks

The lubricants industry is under increasing pressure to deliver peak performance by ensuring machine and system reliability while meeting stringent environmental, health, and safety standards. As industrial, automotive, aviation, and aerospace technologies continue to evolve, the demand for high-performance lubricants capable of operating under extreme tribological conditions has surged.

Addressing the evolving challenges in these industries has been made possible by the use of synthetic base stocks. These stocks are essential in creating advanced lubricants that are specifically designed to meet the emerging demands and unique needs of these sectors.

As environmental regulations become stricter, regulatory requirements for emissions have become more stringent. In response, global markets are increasingly adopting advanced technologies and equipment. These innovations are designed to handle higher power densities efficiently. Consequently, lubricant formulators have been compelled to develop high-performance lubricants and greases that enhance energy efficiency and ensure greater durability under more demanding conditions. This has led to the demand for synthetic lubricants, and therefore the adoption of synthetic base stocks is accelerating worldwide. Their exceptional ability to perform under extreme temperatures, lower emissions, and boost energy efficiency makes them indispensable for next-generation lubricant formulations.

Synthetic Base Stocks: Driving Performance, Efficiency, and Sustainability in Lubricants

Synthetic base stocks are advanced lubricant fluids formulated to surpass the performance of conventional mineral oils. Produced through chemical synthesis, they offer outstanding thermal stability, excellent oxidation resistance, and precise viscosity control across a wide range of temperatures. Compared to mineral base oils from API Group I to Group III, synthetic base stocks offer significantly improved low-temperature fluidity and overall durability. Additionally, some synthetic base stocks, such as certain esters, enhance biodegradability while contributing to the renewability of carbon sources.

The American Petroleum Institute (API) has categorized base oils into five categories as per API 1509. Groups I, II and III are derived from petroleum crude oil, i.e., sourced from the refineries. For instance, Group I and Group II base oils are produced in India mainly from refineries of Hindustan Petroleum Corporation, Bharat Petroleum Corporation, and Indian Oil Corporation.

Group III base oils are produced by hydrocracking, hydroisomerization, and hydrotreating, which make this grade more refined. These base stocks are produced from refineries like Neste, S K, S-Oil, ADNOC, GS Caltex, Petronas, etc.

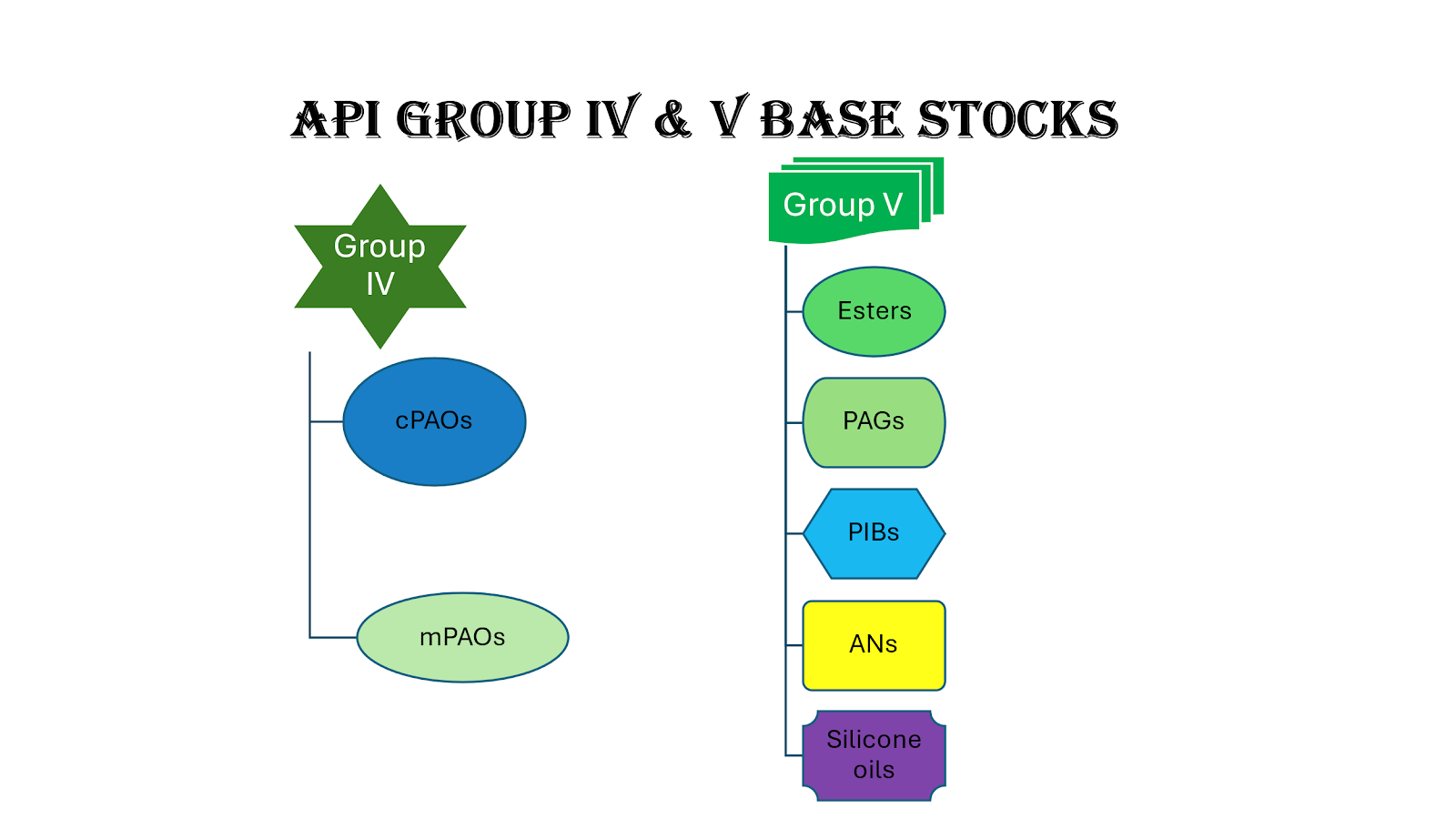

Understanding API Group IV Base Stocks: The Key to Synthetic Lubrication

Synthetic base stocks start from API Group IV and are employed to formulate fully synthetic lubricants, whether automotive, aerospace, aviation, or industrial. They are also used to make speciality greases. API Group IV base stocks consist exclusively of polyalphaolefins (PAOs).

Polyalphaolefins (PAOs)

Polyalphaolefins (PAOs) are fully synthetic base oils manufactured through a precise polymerization process. They are synthesized from alpha-olefins, mainly 1-decene, which is obtained from ethylene through an oligomerization reaction. Linear alpha-olefins (LAOs) serve as feedstocks for PAOs. In some facilities, there is an integration of Alpha-Olefins & PAOs production as Ethylene is produced from Ethylene Cracking, which acts as the primary feedstock. Further, oligomerization converts ethylene into linear alpha-olefins, i.e., 1-decene. Alpha-olefins are polymerized into PAOs using metallocene catalysts, producing metallocene PAOs.

Polyalphaolefins are employed for making various high-end synthetic engine oils, gear oils, and speciality greases due to their intrinsic unique properties.

Let’s try to decode PAOs by understanding their characteristics and application areas:

Key Characteristics of Group IV Base Stocks (PAOs):

- Fully Synthetic - PAOs are produced via chemical synthesis and lubricants formulated from it are fully synthetic.

- Superior Thermal Stability - PAOs perform well under extremes of temperatures and thereby become eligible candidates for speciality applications like aviation lubricants, synthetic gear oils, etc.

- Excellent Oxidation Resistance - PAOs extend lubricant life and reduce sludge formation.

- Wide Operating Temperature Range - Due to low pour points and high viscosity indices, can operate at wider temperature zones.

- Low Volatility - Due to their low volatility PAOs can reduce oil consumption in high-temperature applications.

- Superior Lubricity - Reduces friction and wear for enhanced equipment protection.

Common Application Areas of Group IV Base Stocks (PAOs):

✔ Automotive and industrial lubricants

✔ High-performance engine oils

✔ Aviation and aerospace lubricants

✔ Hydraulic and gear oils

✔ Compressor and turbine oils

Polyalphaolefins (PAOs) are produced by a few specialized manufacturers globally, as these companies have expertise in synthetic base stock production and alpha-olefin feedstock processing. Each producer of PAOs has unique production capabilities, technological advancements, and product performance strengths.

PAOs are available in a range of viscosities, starting from as low as 2 cSt for low-viscosity grades and 40 cSt and above for high-viscosity variants. These are commonly referred to as Low-Vis PAOs and High-Vis PAOs.

Metallocene Polyalphaolefins (mPAOs)

A new advancement in PAOs is Metallocene Polyalphaolefins, commonly, referred to as mPAO which represent the next generation of synthetic base oils, offering superior performance compared to conventional PAOs. They are produced using metallocene catalysts, which provide precise molecular control, leading to improved viscosity, oxidation stability, and energy efficiency in lubricants. Metallocene PAOs are revolutionizing synthetic lubricants, providing enhanced durability, efficiency, and sustainability.

✅ A highly uniform molecular structure, ensuring more predictable and stable lubrication characteristics.

✅ A higher viscosity index (VI), enabling reliable performance across a broad temperature range.

✅ Lower volatility, minimizing evaporation losses even in high-temperature conditions.

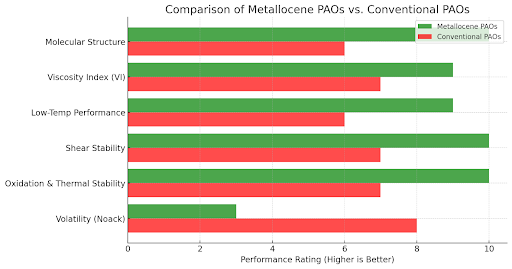

Comparison of Metallocene PAOs and Conventional PAOs

| Property | Metallocene PAOs (mPAOs) | Conventional PAOs (cPAOs) |

|---|---|---|

| Molecular Structure | More uniform and precisely controlled | Broad molecular weight distribution |

| Viscosity Index (VI) | Higher (typically 140–160), offering better stability across temperatures | Moderate (120–140), with relatively lower stability |

| Low-Temperature Performance | Superior flow characteristics and lower pour point | Decent cold-weather performance but less optimized |

| Shear Stability | Exceptional resistance to viscosity loss | Good but prone to some shear thinning |

| Oxidation & Thermal Stability | Enhanced durability, contributing to longer lubricant life | Moderate stability under high heat conditions |

| Volatility (Noack) | Lower evaporation rates, making it more suitable for high-temperature applications | Higher tendency to evaporate under extreme heat |

Comparison of Metallocene PAOs vs. Conventional PAOs

NB- The higher values indicate better performance, except for Volatility (where lower is better).

Applications of Metallocene PAOs

✔ High-Performance Engine Oils

✔ Used in API Group IV+ synthetic lubricants

✔ Enhance fuel economy and engine durability

Industrial Gear Oils

✔ Provide superior wear protection under extreme loads

✔ Maintain viscosity in high-temperature environments

Aviation & Aerospace Lubricants

✔ Ensure low volatility and oxidative stability

✔ Perform well in extreme cold and high-heat conditions

Wind Turbine Lubricants

✔ Long drain intervals reduce maintenance costs

✔ Improve efficiency of gearbox operations

Electric Vehicle (EV) Lubricants

✔ Low friction reduces energy loss in e-mobility systems

✔ Compatible with high-speed electric motors

Key drivers for metallocene PAOs are growing demand by OEMs for higher fuel efficiencies coupled with a long life of lubricants. Another motivating factor for mPAOs is the adoption of electric vehicles (EVs).

Leading producers of metallocene PAOs include ExxonMobil, Chevron Phillips, INEOS and NACO. These advanced synthetic base stocks are gaining significant traction in the lubricant industry due to their distinct molecular structure and superior performance attributes. Notably, their excellent low-temperature fluidity, shear stability, and minimal volatility at high temperatures (low Noack volatility) make them highly suitable for high-performance lubricants across multiple sectors. Key applications include aerospace, aviation, automotive (particularly long-drain and fuel-efficient engine oils), and industrial operations such as windmills, mining, steel, and cement production.

Exploring Group V Base Stocks: Versatility Beyond Conventional Lubrication

API Group V base stocks are a diverse category of base oils that do not fall under the classifications of Groups I-IV as defined by the American Petroleum Institute (API). These base stocks include Esters (synthetic and natural), Polyalkylene Glycols (PAGs), polyisobutenes (PIBs), alkylated naphthalene (AN), silicone oils and other specialty synthetics. They offer unique performance benefits, including superior thermal stability, biodegradability, and enhanced lubricity, making them suitable for high-performance and environmentally sensitive applications.

API Group V base stocks play a vital role in the evolving lubricant industry by offering superior performance, environmental benefits, and application versatility. As the demand for synthetic and sustainable lubricants grows, these base stocks will continue to drive innovation and development in lubrication technology. Their future will be shaped by advancements in additive chemistry, evolving industry regulations, and new market opportunities in electric vehicles and high-performance applications.

Let’s explore some of the key base stocks of this group in brief:

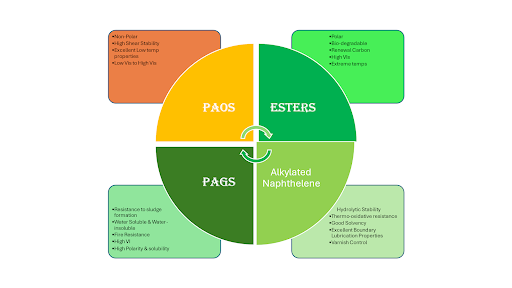

Polyalkylene Glycols (PAGs) - A Versatile Synthetic Base Stock

Polyalkylene Glycols (PAGs) belong to the API Group V base oil category and are distinguished by their excellent lubricity, outstanding thermal stability, and minimal sludge formation. Unlike conventional mineral oils, PAGs can be either water-soluble or water-insoluble, allowing for versatility across various industrial applications.

Let’s understand some of the notable properties and benefits of PAGs as hereunder-

✅ Exceptional Thermal Stability - Resistant to oxidation and thermal breakdown, ensuring extended service life.

✅ High Viscosity Index - Maintain stable viscosity across fluctuating temperatures.

✅ Minimal Sludge Formation - Help keep systems clean, reducing maintenance needs.

✅ Fire Safety - Certain PAG formulations possess self-extinguishing characteristics, making them suitable for fire-resistant fluids.

✅ Environmental Compliance - Many PAGs are biodegradable, supporting eco-friendly lubrication solutions.

✅ Superior Lubricity - Enhance wear protection and minimizes friction in demanding applications.

Industrial and Automotive Uses:

✔ Compressor Oils - Preferred in refrigeration, air, and gas compression systems due to their oxidation resistance and low volatility.

✔ Fire-Resistant Hydraulic Fluids - Ideal for industrial setups where non-flammable lubricants are required.

✔ Gear Lubricants - Provide strong film strength and high load-bearing capacity in gear applications.

✔ Metalworking Fluids - Applicable in machining for cooling and lubrication efficiency.

✔ Electric Vehicle (EV) Applications - Utilized in transmission fluids due to their dielectric nature.

With the growing demand for high-performance and environmentally friendly lubricants, PAGs are expected to play an increasingly significant role in the future of synthetic lubrication technology.

Polyisobutylenes (PIBs) - The Versatile Viscosity Modifier

Polyisobutylenes (PIBs) are specialty base stocks categorized under API Group V, valued for their ability to enhance viscosity, resist oxidation, and improve tackiness. These polymers serve as critical components in lubricant formulations, optimizing film strength, reducing evaporation losses, and maintaining stability across a range of temperatures. Available in various molecular weight grades, PIBs offer versatility in applications spanning industrial lubricants, fuel additives, and sealants.

Let’s delve into some of their distinctive features and performance benefits as hereunder:

✅ Effective Viscosity Boosting - Contribute to improved lubricant film integrity and load-bearing capacity.

✅ Superior Oxidation and Heat Resistance - Enhance lubricant durability under extreme conditions.

✅ Low Volatility - PIBs are ideal for high-temperature environments as they minimize evaporation losses.

✅ Adhesion & Tackiness - Improve lubricant cling in applications such as chain oils and wire rope lubricants.

✅ Outstanding Shear Stability - Maintain viscosity even under high mechanical stress, ensuring prolonged lubrication.

Common Applications

✔ Engine & Gear Oils - Function as a viscosity modifier, improving wear protection and overall lubricant stability.

✔ Two-Stroke Engine Oils - Help control deposits and lowers exhaust smoke emissions.

✔ Adhesive & Tackified Lubricants - Essential for chain oils, wire rope lubricants, and specialized industrial greases.

✔ Fuel Additives - Act as a dispersant in gasoline and diesel fuels to minimize deposit formation.

✔ Sealants & Grease Formulations - Enhance water resistance and sealing efficiency in industrial applications.

With the increasing demand for high-performance and environmentally friendly lubricants, PIBs continue to play a crucial role in modern formulations by providing superior viscosity control and film strength.

Alkylated Naphthalene (AN) - A High-Performance Base Stock

Alkylated naphthalenes (ANs) are synthetic base stocks categorized under API Group V, renowned for their remarkable resistance to oxidation and exceptional thermal stability. They seamlessly blend with various base stocks, enhancing lubricant performance under extreme conditions. They act as a high-performance alternative to traditional mineral oils and are often used as a co-base stock or additive to enhance lubricant durability in extreme conditions. ANs exhibit excellent solvency and lubricity, akin to esters, yet they provide superior resistance to hydrolytic degradation.

This category of synthetic fluids exhibits exceptional thermo-oxidative and hydrolytic stability, along with low volatility and excellent solubility characteristics. Additionally, recent studies on electrohydrodynamic (EHD) film thickness and pressure-viscosity coefficients highlight their strong performance, making them a viable alternative to synthetic esters.

Let’s have a look at some of the key attributes and advantages along with application areas of alkylated naphthalene as hereunder-

Key Attributes and Advantages:

- Exceptional Oxidation Stability: Extends lubricant lifespan by preventing sludge accumulation due to enhanced resistance to sludge formation.

- Robust Thermal Stability: Maintains performance integrity under high-temperature operations.

- Effective Solvency: Enhances additive solubility as well as good compatibility with various lubricant formulations, helping in optimizing lubricant formulations.

- Wear and Friction Mitigation: Enhances equipment efficiency and longevity due to improved lubrication efficiency.

- Reduced Volatility: Minimizes oil consumption in high-temperature applications.

Some of the application areas of alkylated naphthalene can be:

- Industrial and Automotive Lubricants: Integral in formulating engine oils, gear oils, and turbine oils for improved durability.

- High-Temperature Environments: Ideal candidate for compressor oils, thermal transfer fluids, and high-temperature chain oils.

- Greases: Boosts oxidative stability and extends the service life of high-performance greases.

- Synthetic Lubricant Formulations: Often combined with PAOs and esters to achieve desired performance characteristics. In some of the formulation(s), it even replaces the esters.

- Glass Moulding Fluids: Preferred for their exceptional thermal and oxidative resilience.

As the demand for high-performance lubricants continues to grow, Alkylated Naphthalenes (ANs) are emerging as a preferred base stock. Their excellent balance of oxidative stability, additive compatibility, and thermal efficiency makes them an attractive choice for lubricant manufacturers.

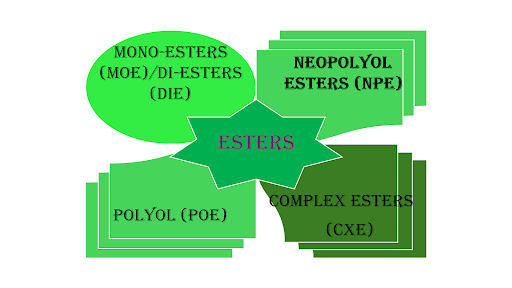

Esters — High-Performance Synthetic Base Stocks

Esters are one of the most widely used API Group V base stocks, known for their outstanding thermal stability, lubricity, and biodegradability. Esters can be synthetic as well as natural, and they are derived from the reaction of acids and alcohols. Therefore, esters can be designed in various ways, selecting the right acid(s) and alcohol(s) and creating molecular structures that offer superior performance compared to conventional base oils. Esters are commonly classified into Monoesters (MOE), Di-esters (DIE), Polyol esters (POEs), Neopolyol Esters (NPE) and Complex esters (CXE), each designed as per requirements for specific lubrication application/s.

Let’s study some of the key properties and advantages of Esters-

- High Thermal and Oxidation Stability: Enable operation in extreme temperatures, extending lubricant life.

- Superior Lubricity - Reduce friction and wear, enhancing component durability.

- Excellent Solvency - Improve additive dispersion, ensuring optimal lubricant performance.

- Low Volatility - Reduce oil loss and evaporation at high temperatures.

- Lower Coking Propensity - Esters have a low coking propensity, thereby making them eligible for speciality applications in the aviation sector.

- High Viscosity Indices - Esters have higher viscosity indices, thereby finding employment in HVI hydraulic oils and other high-end lubricants.

- Low Pour Points & Higher Flash Points - Esters demonstrate excellent extreme temperature properties both in the lower zone and higher temperature zones.

- Biodegradability and Renewability - Many esters are biodegradable, renewable, and widely used in formulations that comply with environmental regulations for eco-friendly lubricants.

Let’s understand some of the unique application areas of the esters:

- Aviation and Aerospace Lubricants: Synthetic esters excel in extreme temperatures and offer high thermo-oxidative stability. These properties make them ideal base stocks for aviation and aerospace lubricants. Most jet engine and turbine oils are formulated using esters.

- Automotive and Racing Oils: Preferred in high-performance engine oils for superior wear protection.

- Biodegradable Hydraulic Fluids: Essential in environmentally sensitive applications like forestry and marine industries to protect the environment.

- Compressor and Refrigeration Oils: Offer excellent lubrication in high-pressure and low-temperature conditions.

- Metalworking Fluids and Greases: Enhance lubricity and stability in demanding industrial processes.

- Transformer Oils: Esters due to their unique combination of various properties like higher fire/flashpoints, biodegradability, excellent di-electric and thermos-oxidative properties, make it the most suitable candidates for transformer oils and readily acceptable in this industry.

- Refrigeration Oils: Another unique application area for esters are refrigeration industry, wherein POEs are compatible with chlorine-free refrigerants like HFCs and Group I/II/III are not compatible. Therefore, for all industrial refrigeration application areas like chillers, cold chains, cold storage, etc., using HFCs refrigerants, esters are only the choice for lubricant companies.

Due to their exceptional performance characteristics, esters continue to be a vital component in advanced lubricant formulations, offering sustainability and efficiency across various industries.

Synthetic Base Stocks

Conclusion (Driving the Future of Lubrication)

The demand for synthetic base stocks is increasing, fuelled by stricter environmental regulations, advancements in technologies & the growing need for high-performance lubricants. Emerging markets—such as India, Southeast Asia, the Middle East, Africa, Latin America, and Eastern Europe—are at the forefront of this shift, offering substantial growth potential.

Some of the key growth drivers for synthetic base stocks include the shift towards electric vehicles (EVs), the industry's focus on reducing maintenance and operating costs, and the need to minimize downtime in industries. Moreover, evolving OEM specifications and the push for better fuel efficiency, extended oil drain intervals, and enhanced performance continue to propel the demand for synthetic base stocks.

Growing sustainability efforts and regulatory mandates are pushing the demand for environmentally friendly lubricants with a reduced carbon footprint, particularly those derived from renewable sources. This trend is driving greater adoption of advanced base stocks like esters.

As industries strive for greater efficiency and sustainability, synthetic lubricants have emerged as a crucial solution for energy conservation and performance enhancement. Core industries such as mining, iron & steel, cement, power, heavy engineering and others can significantly benefit from this transition, reinforcing the value of synthetic base stocks in optimizing performance and sustainability.

The transition from conventional to synthetic lubricants is no longer a luxury but a necessity for industries. With proven energy savings, extended service life, and reduced environmental impact, synthetic lubricants are a strategic investment for companies seeking long-term operational efficiency and cost reduction.

Maximizing synthetic base stocks' potential in emerging markets requires innovation, investment, local manufacturing, and strategic partnerships. Collaboration among lubricant producers, OEMs, and policymakers will drive the adoption of the next-generation lubricants.

Collaboration among lubricant producers, OEMs, and policymakers will drive adoption and next-generation lubricant development.

As the global lubricant industry evolves, synthetic base stocks will remain at the forefront of innovation, offering sustainable and high-performance solutions to meet the challenges of tomorrow’s markets.