Business Excellence through Plant Reliability: Amalgamation of AI and Engineering to Reach Sustainability

Introduction

Artificial Intelligence (AI) has led to an unprecedented revolution in the Sensor world. The concepts of "sensorization" and "digitalization" have engaged the minds of Research and Development (R&D) Teams across the industries. There is some improvisation on the Technology or Software front on a regular basis. Information Technology (IT) and Operational Technology (OT) are working together to have a smooth interface and crossover agility to harness the unexplored potentials of AI to leverage business output, human safety, and ease of doing things.

In the context of reliability and maintenance of industrial machines, AI has already changed the thought process of the reliability engineers. It has redefined the science of Condition Monitoring and Data Analysis. With AI, the collection of machine-critical operational data, its processing and analytics, problem visualization, and action prompts have become fast and accurate. The key to AI's success in reliability and maintenance entirely depends upon the analyst's understanding of the response mechanism of functional parts of the machines in static, dynamic and energized scenarios.

Multi-physics modelling can be established for each type of Asset Group, considering the effects of stress, strain, and torsional characteristics. The effects of Thermal gradients, media contaminants, harsh environmental conditions, potential human errors (operation and maintenance), etc., must become the ingredients of the AI interpretations. Consequently, the combination of AI and Engineering has become a necessity for every industry that is trying to maximize the benefits and attain Business Sustainability.

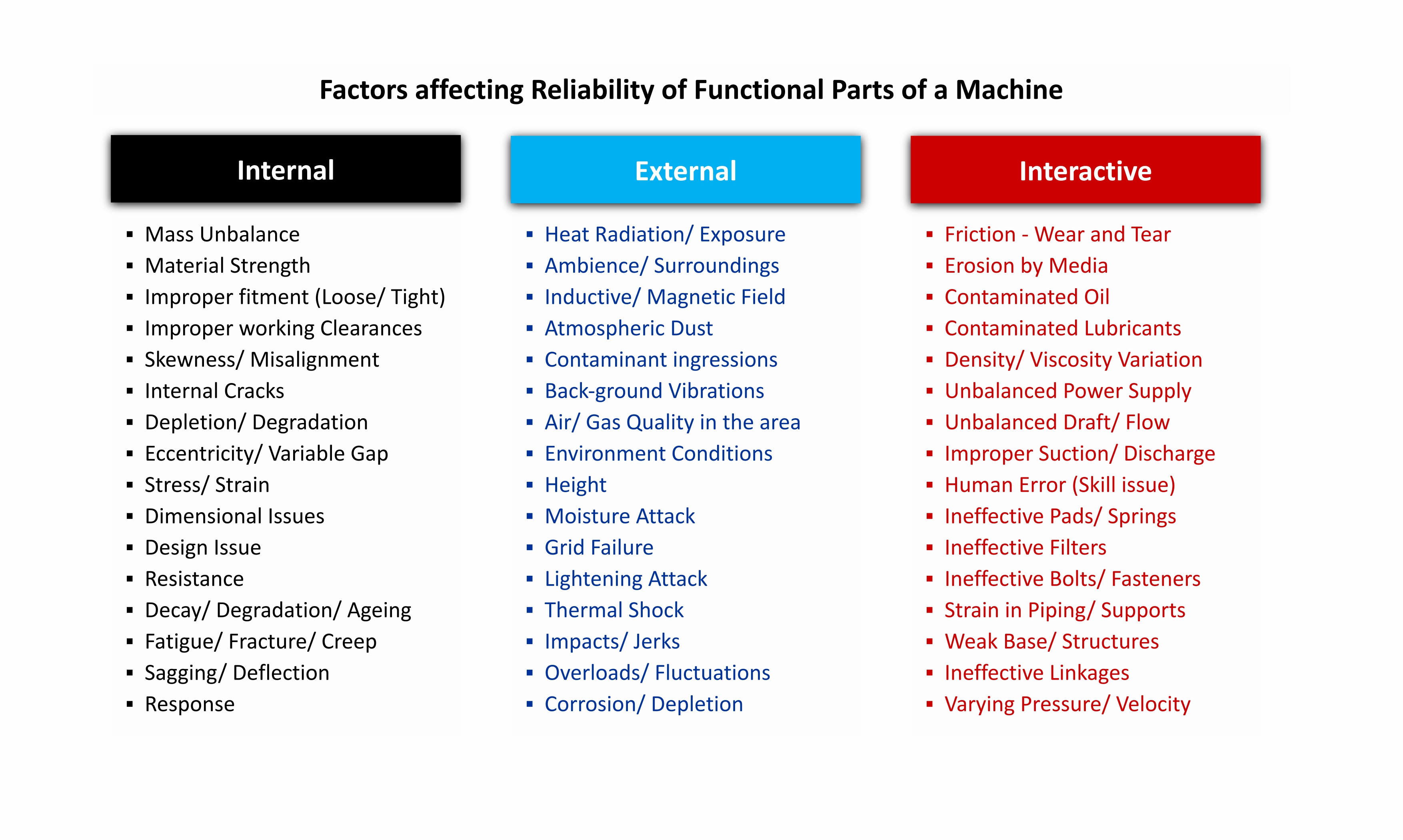

Factors Affecting Machine Reliability

A machine is made up of many parts. Some parts are functional while others are accessories to the system, playing no role in the overall functioning of the machine. Reliability of a machine depends upon the reliability of its functional parts. A functional part fails either by natural deterioration over a period of time or by getting damaged due to undesired forces, which could be internal, external, or interactive.

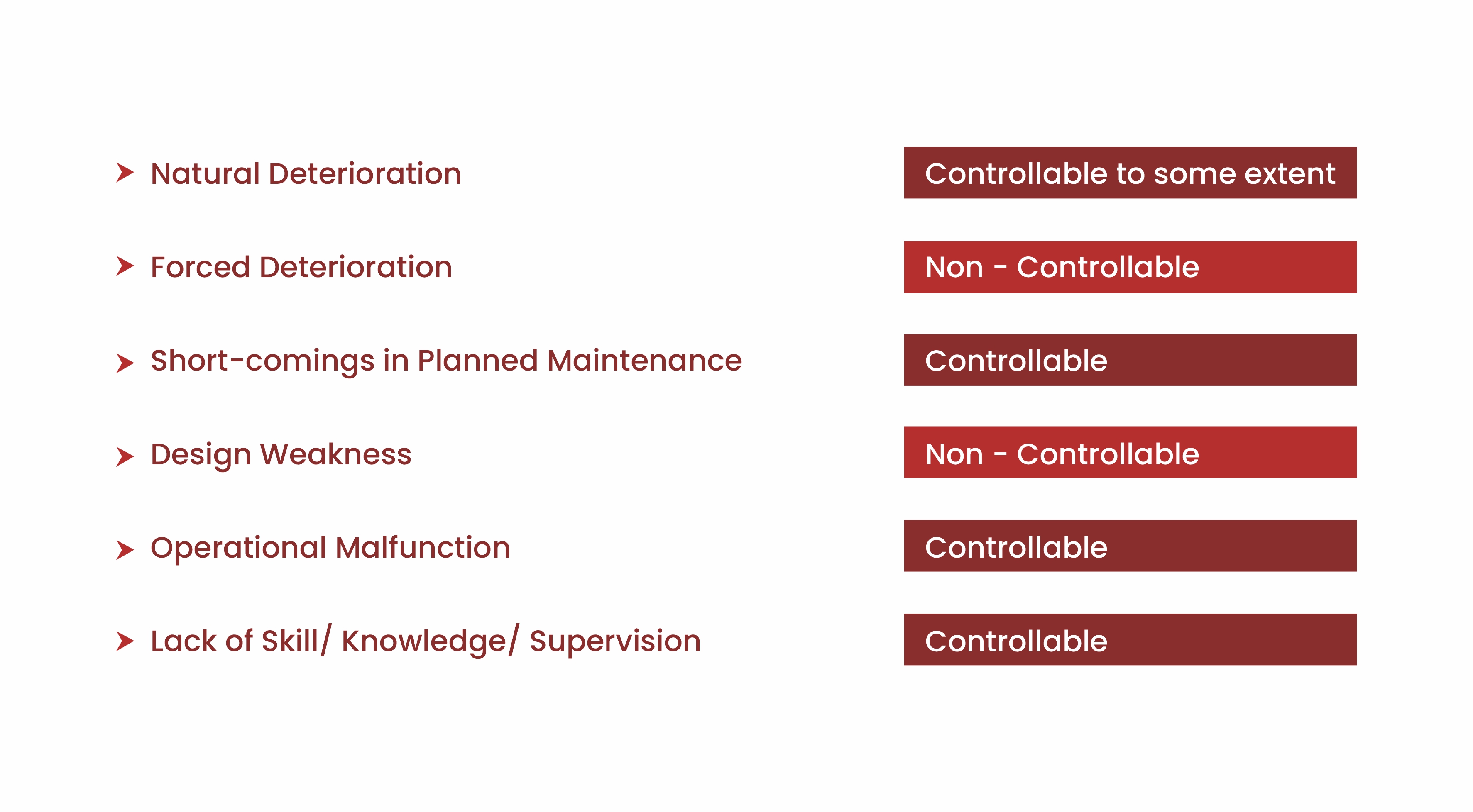

Controllable and Non-Controllable Failures

A machine fails when any of its functional parts fail to perform their functions (as per the Design or intended purpose). At the industry level, some failures are controllable, while some are non-controllable. For example, failures due to natural deterioration are controllable to some extent by following the Standards of Operation and Maintenance. Forced deterioration is unavoidable when the problem is known but corrective actions are not being taken in an attempt to achieve production targets. Similarly, Design Weakness cannot be rectified at the Plant level as it requires lots of Engineering Calculations and Design Knowledge. Controllable and Non-Controllable types of failures are listed here.

Natural deterioration is always desirable because it helps the functional parts to attain their useful service life. This also helps in correct predictions of remaining safe running life, and thus, there are no surprise failures. But the failures due to other reasons are unpredictable and lead to surprise breakdowns. Such failures incur huge production losses, increase O&M costs, and pose great safety risks to man, machine, and material.

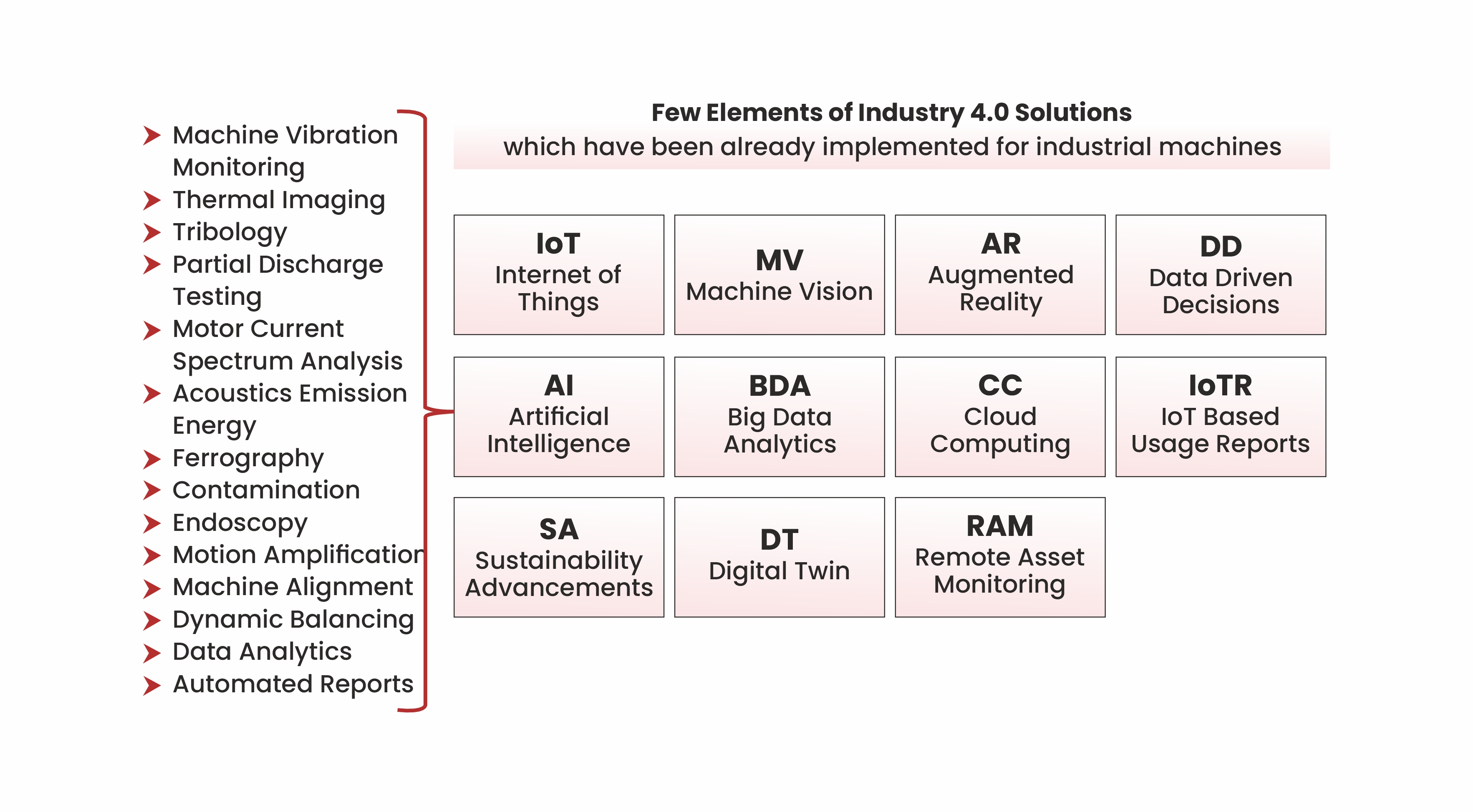

Industry 4.0 Solution Options - AI is a game changer

Surprise failures must be avoided at any cost. In this context, AI is the game-changer. Industry 4.0 solution options have revolutionized AI applications in early detections of the budding-stage problems. To exploit the AI potentials, the reliability engineer must understand machine responses in terms of vibration, sound, temperature, flow, pressure, velocity, current, resistance, voltage, erosion, corrosion, speed, color, contaminants, metal particles, dust ingression, etc. This understanding paves the way for identifying the critical operational data, the effective data sources, and the right type of sensors required. Data Acquisition and Analysis could be in real time or offline. But the data interpretations must end with some corrective or preventive actions.

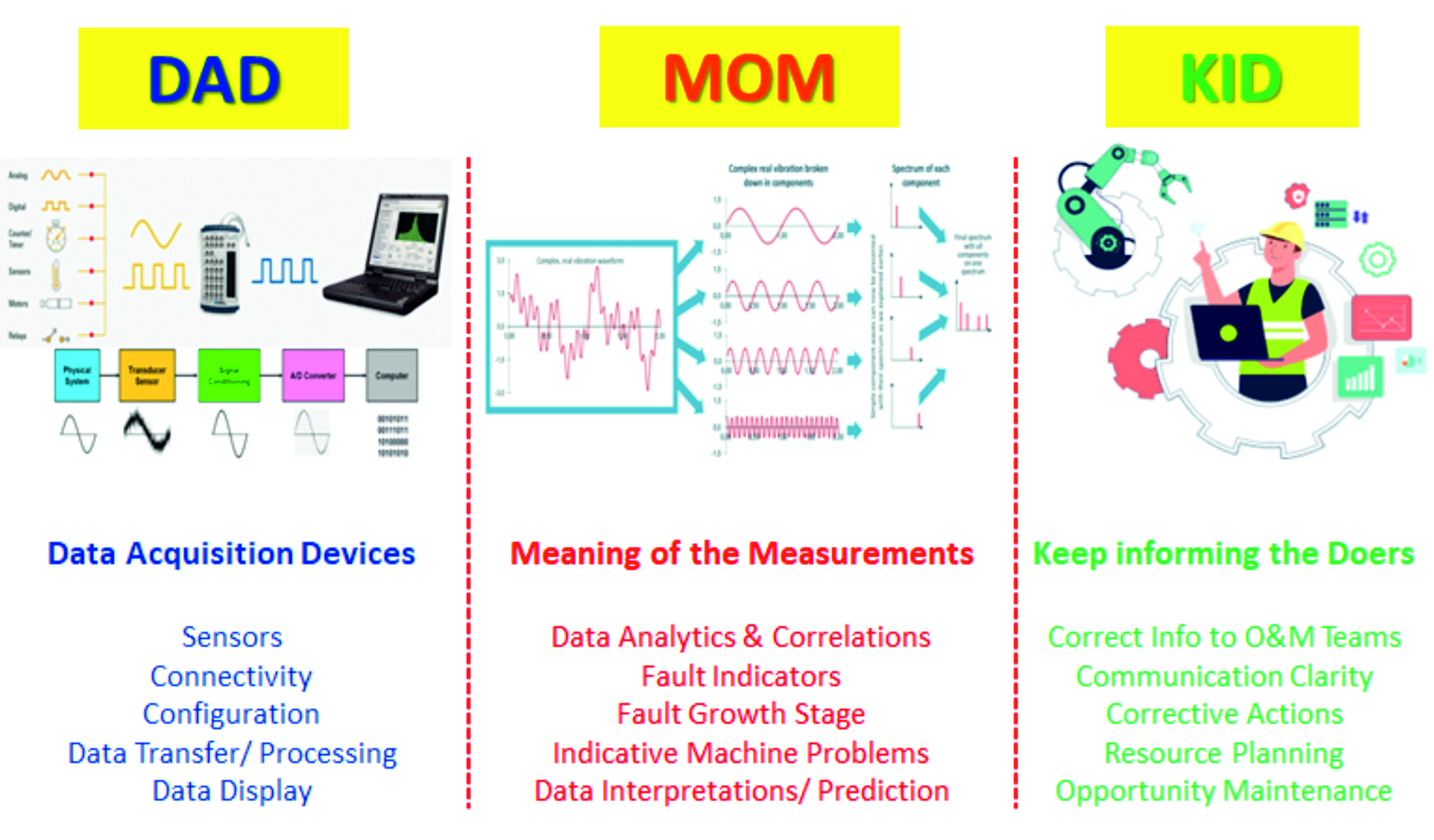

Industry 4.0 solution options have three major components, which form the basis of AI in Reliability:

• DAD (Data Acquisition Devices) - Sensors and instruments for collecting operational data

• MOM (Meaning of the Measurements) - Analytics and interpretation of collected data

• KID (Keep informed the Doers) - Communication and action prompts for maintenance teams

The success of AI for industrial machines depends upon all three combined—DAD, MOM, and KID. None of them can work solo. They must work in sync and in collaboration to harness the potential benefits of AI. Few elements of Industry 4.0 Solutions that have already been implemented for industrial machines are listed below:

Multi-physics modelling and Engineering – Understanding basics of Machine Response

The understanding of response mechanisms helps in formulating some rule-based AI Software to assess the health of machines and predict their worthiness to run further. A machine response could be high vibrations, high temperature, pressure fluctuations, insufficient flow-rate, over-current, excessive sagging, excessive deflection, abnormal wear pattern, shaking, jerks, abnormal sound, breakage, seizure, jamming, incorrect level, over-heating, colour change, texture change, voltage variation, partial discharge, corona formations, burning, smoke, tilting, speed variation, viscosity change, moisture content, humidity, light intensity, etc.

Some basic engineering concepts which help understand the multi-physics modelling involved in assessing the health conditions of any machine are illustrated below. They are quite useful in resolving machine problems.

(1) Machine Vibration – High, Fluctuating, Jerking, Shaking, Resonating

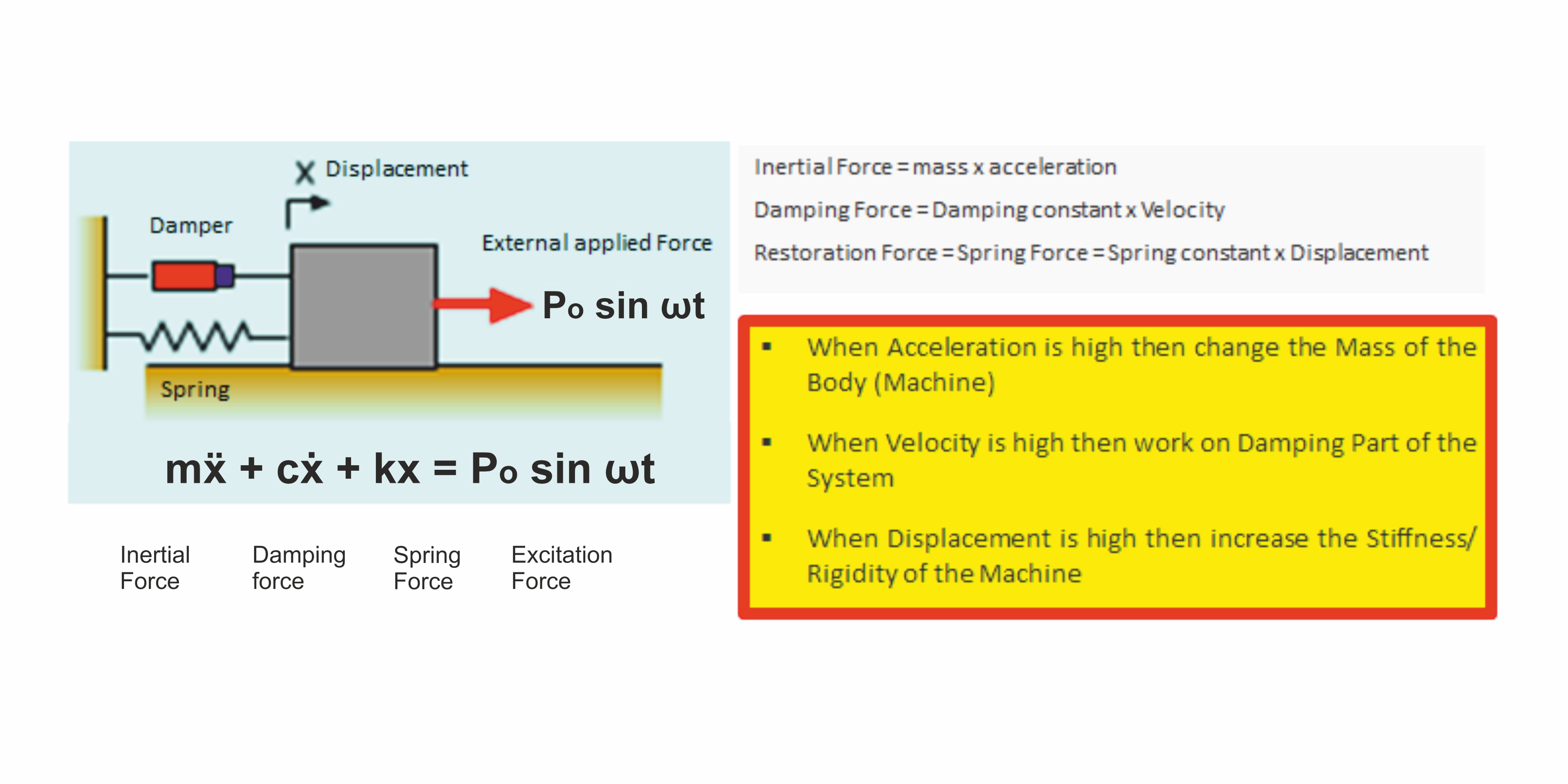

Analyzing a high-vibrating machine could be a difficult task. However, understanding the associated physics involved in terms of applied forces on the machine and the response it can exhibit, the resolution to vibration-related problems becomes easy. The mathematical equation of the vibration force is given below.

The mathematical equation of vibration force clearly aligns with the solution options. Machine vibration is measured in terms of displacement (microns), Velocity (mm/s), and Acceleration (g). Useful tips for solutions are given in the red box, where it clearly mentions what corrective actions have to be taken when acceleration velocity or displacement values are high.

(2) Effect of Temperature on Oil Viscosity

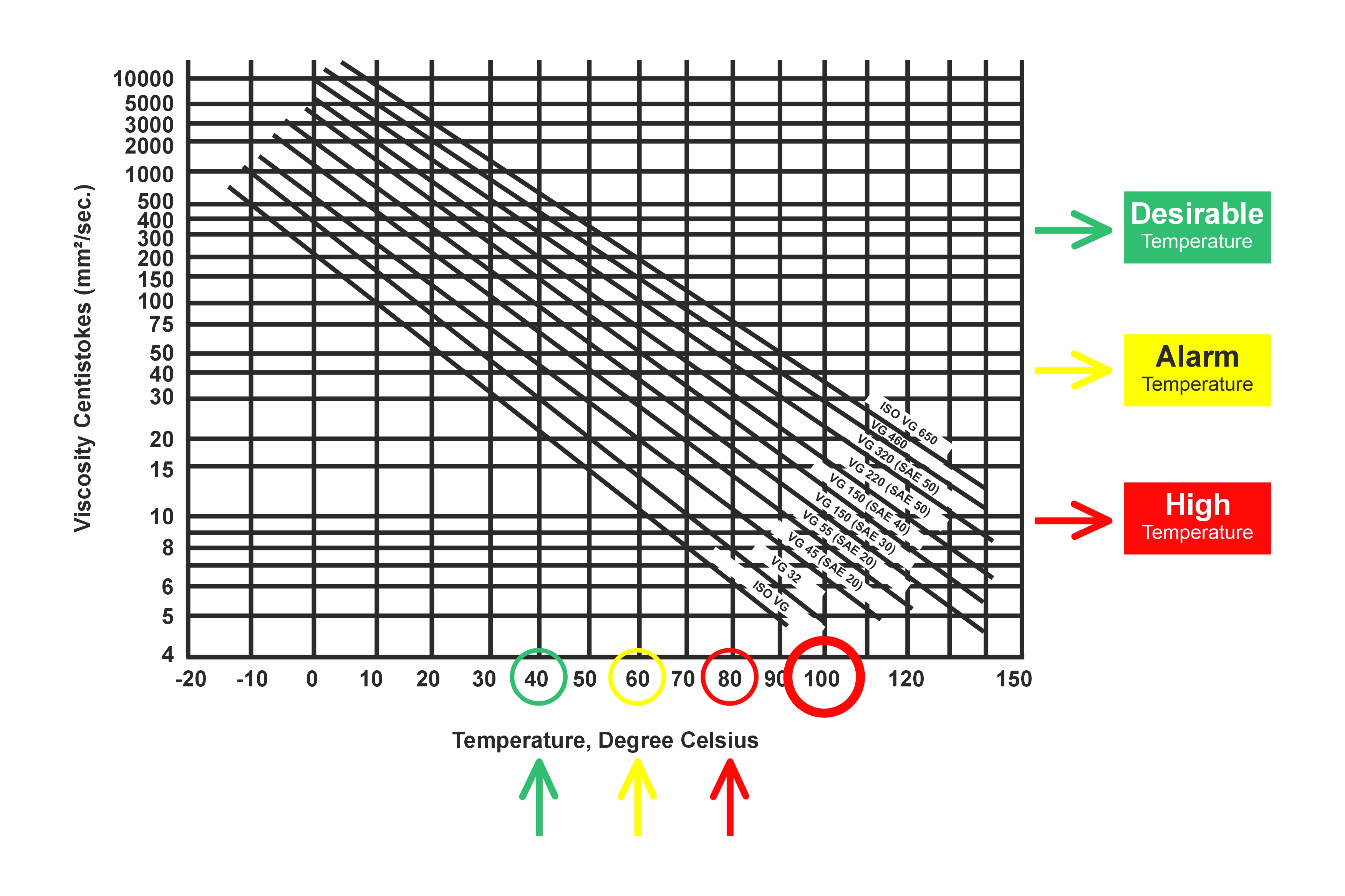

Oil Viscosity is inversely proportional to its temperature. Viscosity decreases when the temperature increases. It means the oil film thickness between the mating surfaces decreases. The load-carrying capacity of bearings and gear teeth or mating surfaces decreases. Metal-to-metal contact causes an exorbitant increase in friction, resulting in abnormal wear and tear of vital engineering components like bearings, seals, gear-teeth etc. So, the oil temperature must always be maintained at the designed operating temperature.

AI can be easily established for the oil temperature when the desirable, alarm, and high values are mentioned. A smart temperature sensor with an AI feature can help in real-time monitoring of the health conditions of the asset. A Viscosity-Temperature graph is given below. It clearly shows how the viscosity changes with regard to the change in temperature.

(3) Selecting Correct Vibration Sensor

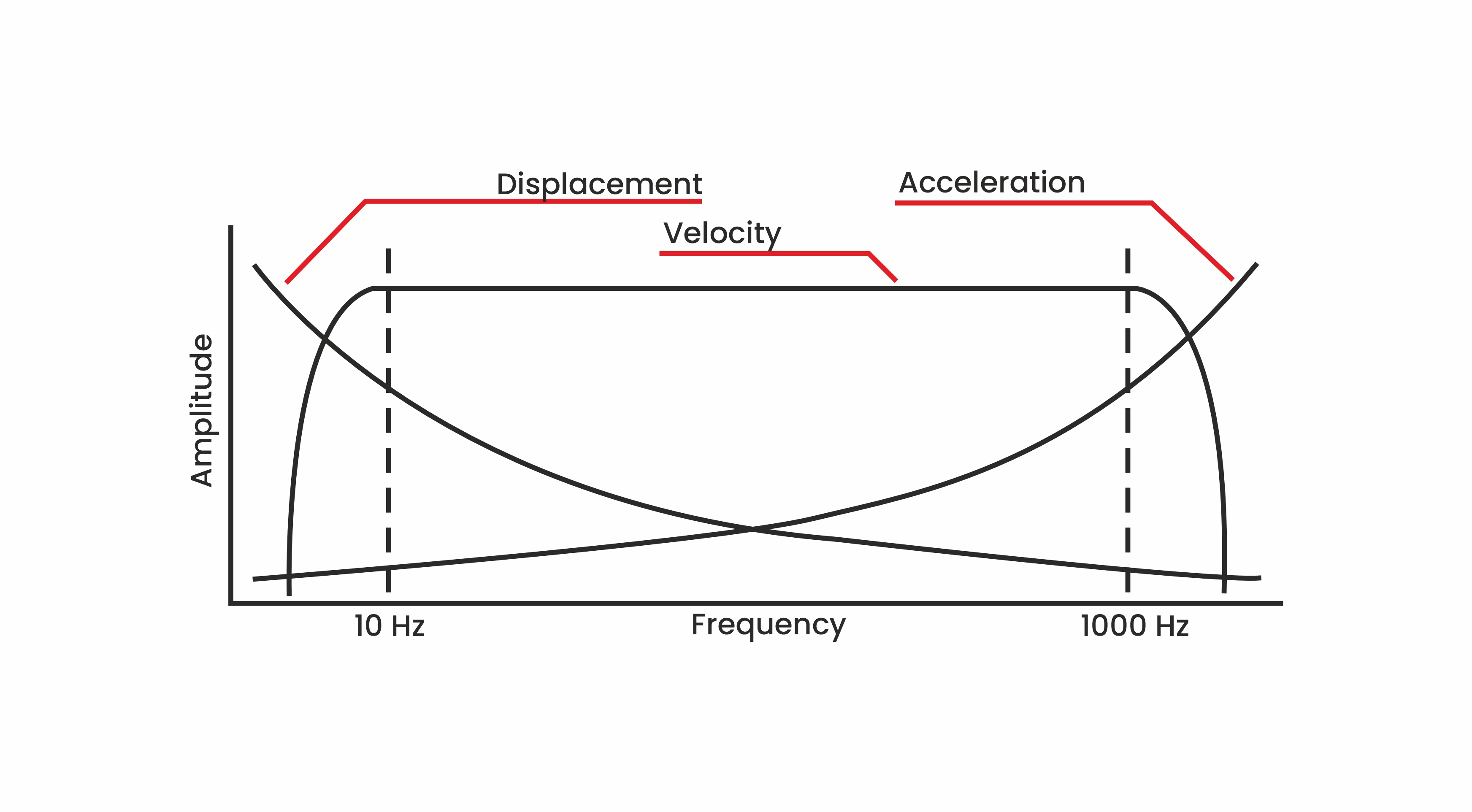

Refer to the below-given Amplitude Frequency Graph showing change in Vibration Amplitude with change in Frequency (rotational speed of machine). It is clear that Velocity is unaffected by the change in Frequency from 10 Hz to 1000 Hz. Displacement shows some decreasing linearity below 10 Hz, while Acceleration shows some linearity at higher frequencies. So Sensor selection becomes easy. Not one type of Sensor is suitable for slow and high rpm machines. While installing on-line Sensors for real-time monitoring, it becomes a must consideration to select the right Sensor which could give the right machine response.

(4) Proximity Vibration Sensors for Turbo-Machinery

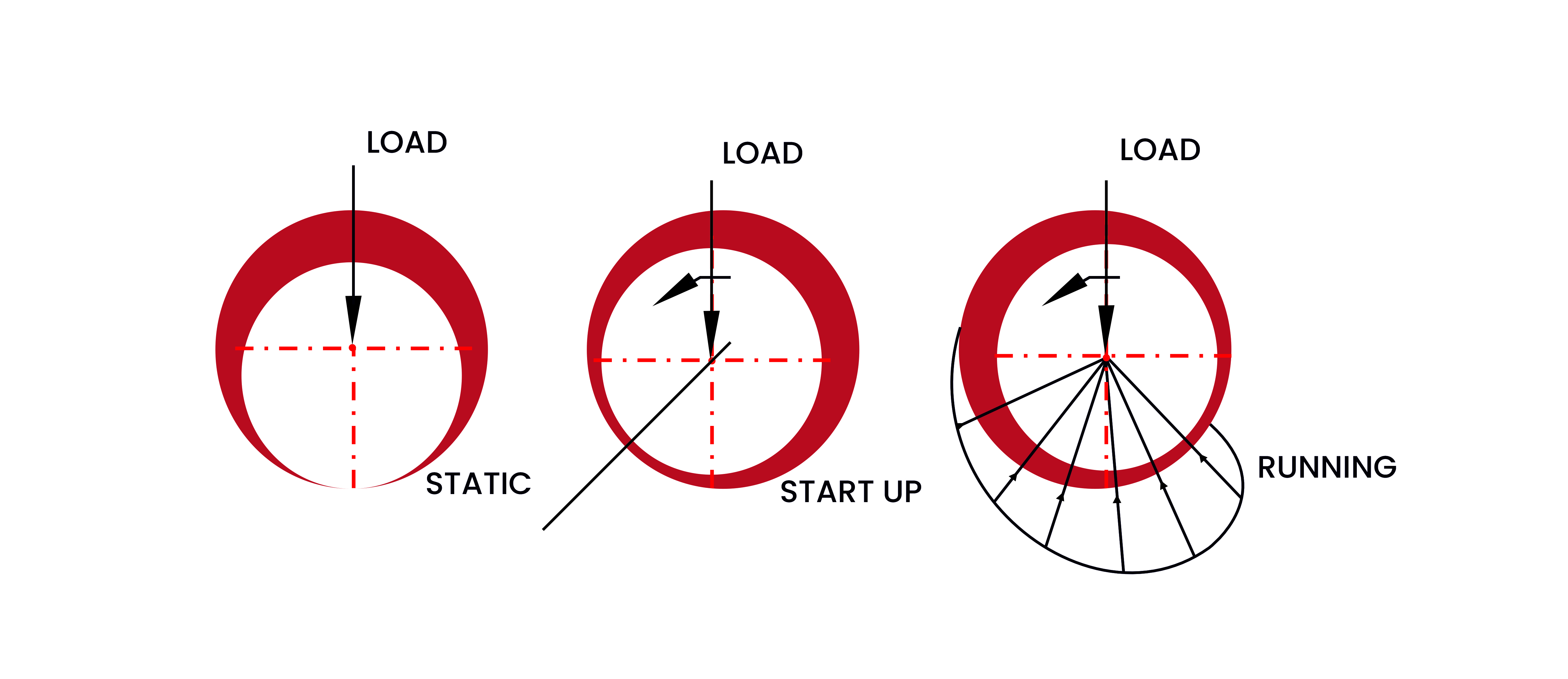

The shaft centreline of a turbomachinery changes its position as shown in the image below. Positioning of proximity shaft vibration probes must be done in such a manner that it traces the rotational eccentricity and the orbit. Eccentricity values and the Orbit graph may be used to establish an AI features for the turbomachinery.

All the above four illustrations are just a mention of the broader concept that goes into establishing AI features for auto-diagnostics and interpretations of the operational data of industrial machines. There could be hundreds of concepts involved in designing a robust AI.

A Few Case-Studies: AI-based diagnostics and troubleshooting of industrial machines

DAD, MOM, and KID form the basis of AI for diagnostics and troubleshooting of critical machines. AI starts with the right DAD, a superb MOM, and an effective KID. A few case studies are discussed here:

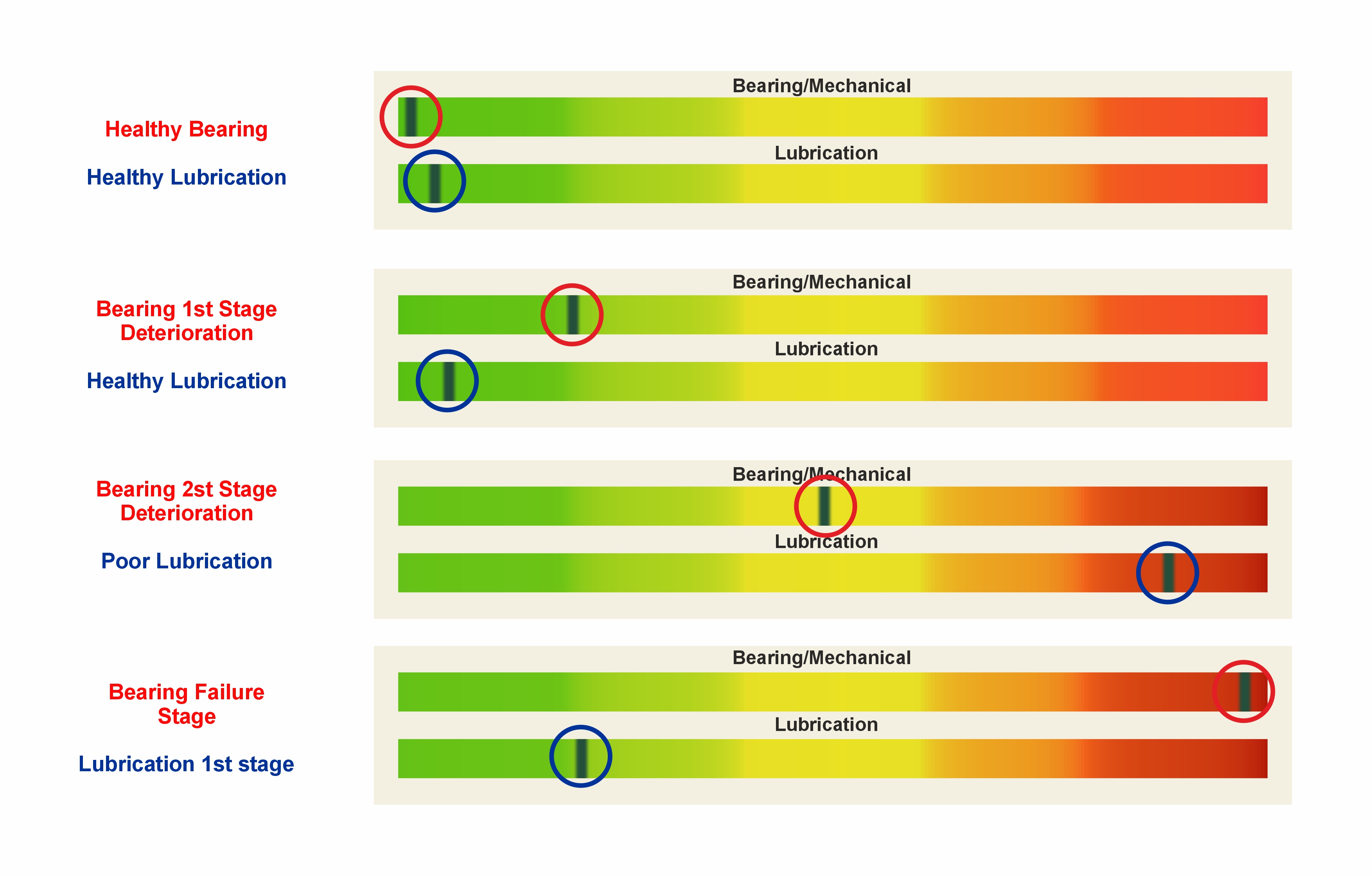

(1) AI-based Health Predictions of an anti-friction Bearing and Lubricant

The reliability of rotary machines is primarily governed by the health of bearings and lubricants. Advanced instruments with AI features can detect the abnormalities of Bearings and Lubricants. No human interpretation required. Refer to the below-given AI-based interpretation graph, which shows the deterioration stages of Bearings and the Lubricants.

The above AI Graph shows the stages of deterioration, which helps to accurately predict the remaining useful life of Bearings and Lubricants. The deterioration stages can be tracked to avoid Surprise Failures.

The AI feature has helped instant analysis and quick maintenance decisions. With conventional methods, it would have taken a lot of human effort and time in analyzing the frequency faults and lubricant condition. It would have necessitated the involvement of an experienced rotary machine analyst to find out the abnormalities. Delayed and suspected analysis ultimately leads to delayed maintenance decisions, risking the critical machines failing.

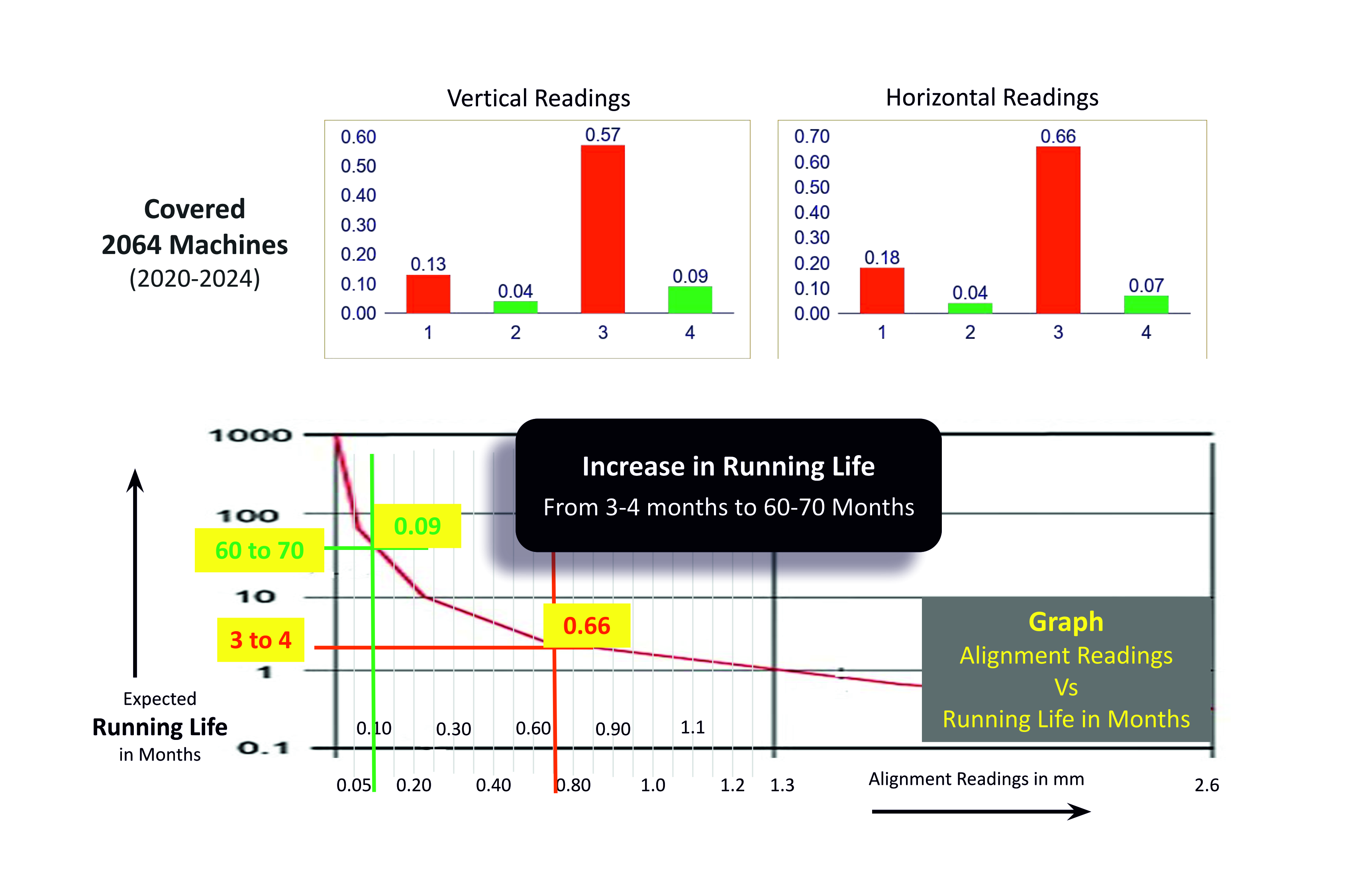

(2) AI based precision Leveling and Alignment

Base levelling issues, coupling misalignment, soft footing, piping strain, bolts in tension, bent shafts and improper axial gaps cause rotational excessive stress on the supporting points (Bearings) and the linkages (Couplings and Bolts) resulting in almost 50% of the premature surprise failures of functional parts of rotating machines. AI has greatly helped in achieving precision Alignment values much below the permissible levels. This has led to the reductions in surprise failures and an increase in the bearing life. Refer to the below-given graph showing the impact of precision alignment on more than 2000 rotary machines.

In the last 4 years, more than 2000 rotary machines were covered under precision alignment using AI-based instruments. As per the above Graph (Running Life of Bearings wrt Alignment Tolerances), the average bearing life increased from 3 months to 60 months. AI helped to achieve the lowest alignment tolerances, which ultimately increased the reliability of bearings.

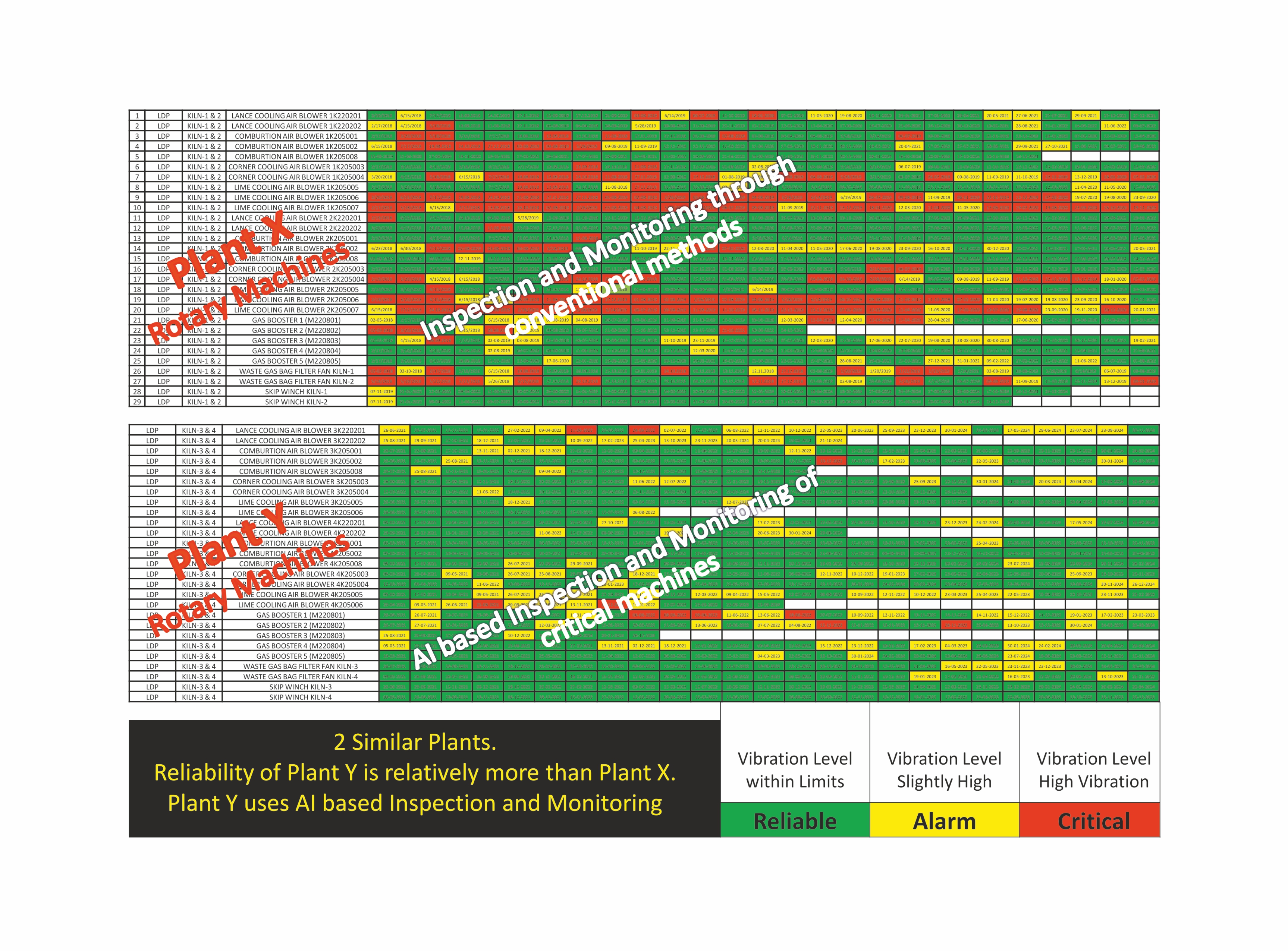

(3) Impact of AI-based Inspection and Monitoring on overall Reliability of critical Rotary machines

Both Plant X and Plant Y are similar in all respects—capacity, equipment and make. Plant X used conventional methods of inspection and monitoring. Most of the equipment was in Yellow (alarm) and Red (critical) zones. Plant Y started using AI-based Inspection and Monitoring since its commissioning.

AI helped in pointing out the reasons for budding-stage abnormalities in the machines. Corrective actions were taken. Preventive action points were chalked out and implemented. The result is all visible. Plant Y Reliability is relatively more than Plant X. Plant Y's reliability matrix has maximum greens, while Plant X has maximum reds.

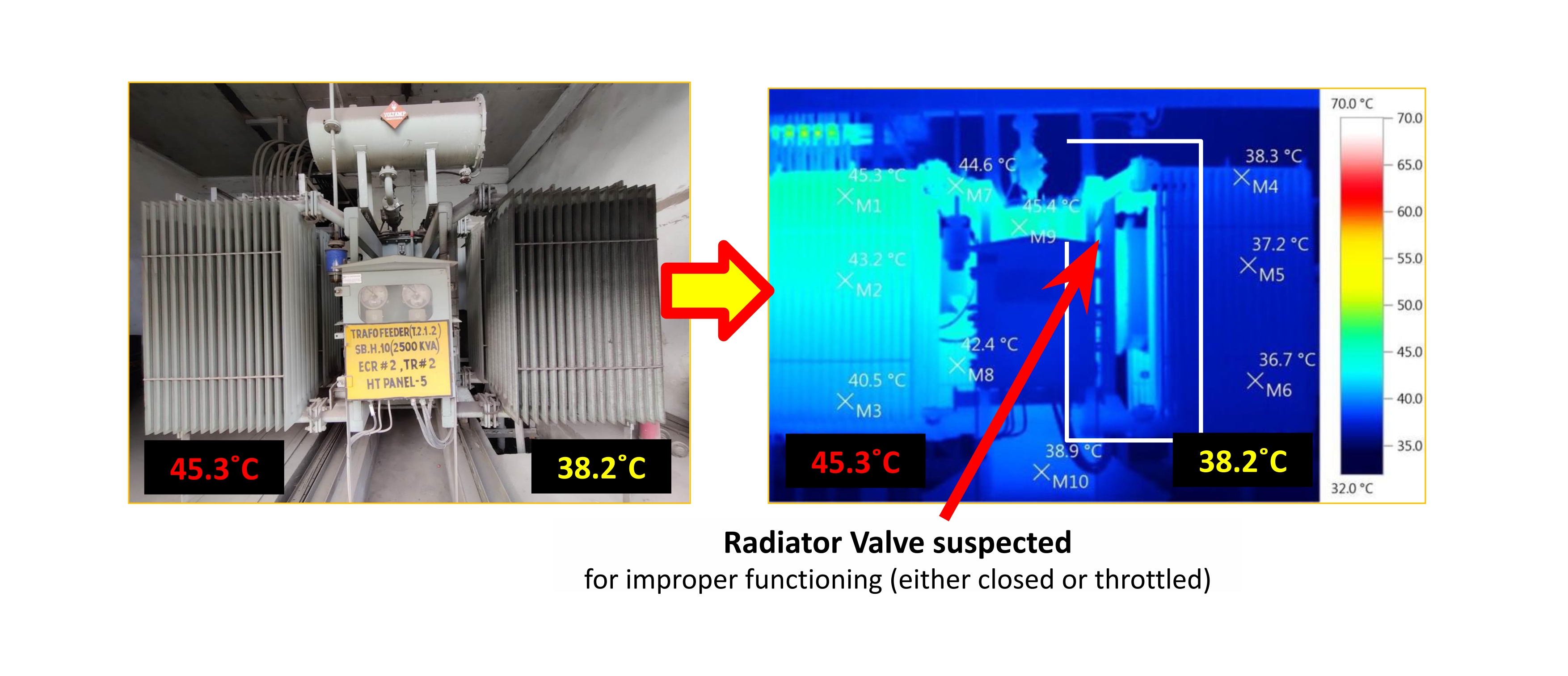

(4) AI helps in Problem Visualization by Human Senses

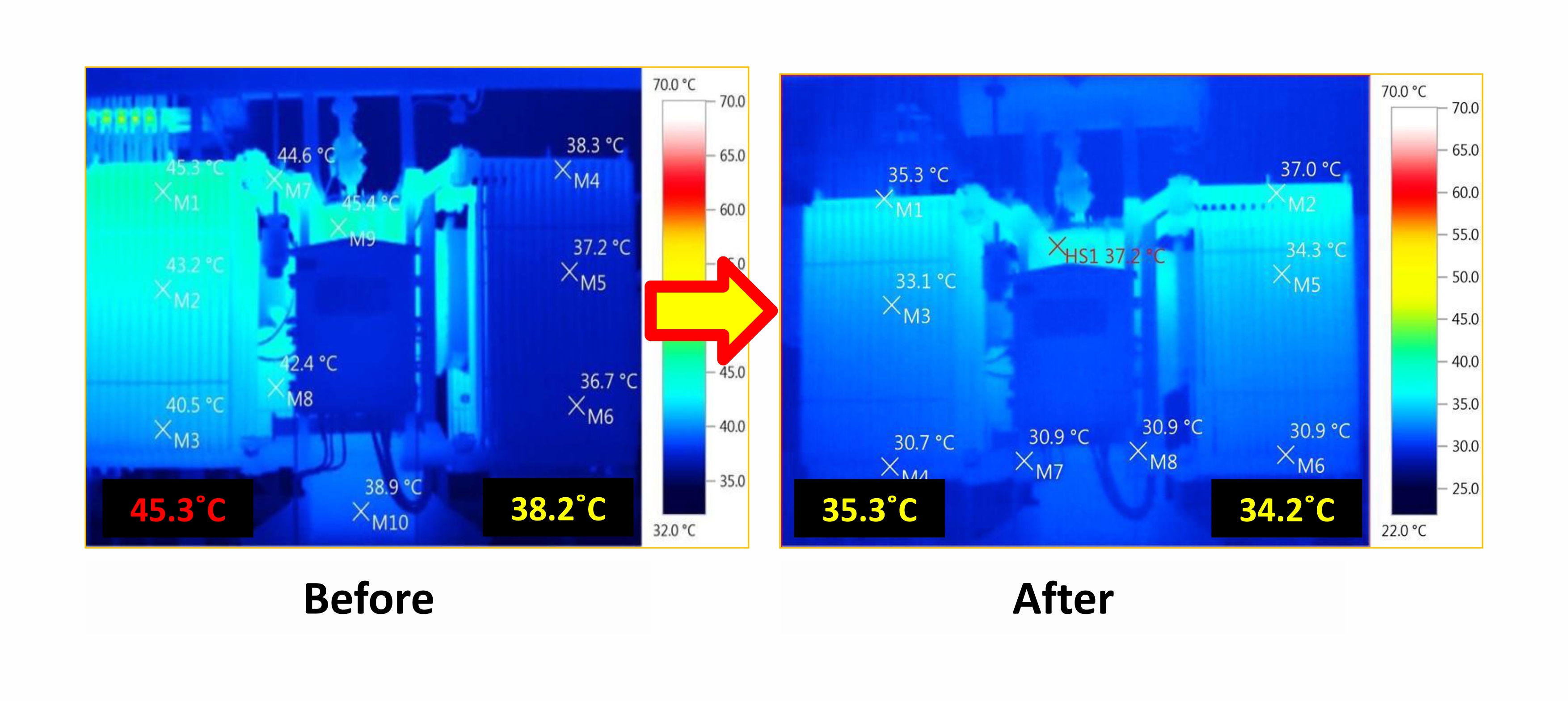

In one of the transformers (2500 KVA), the infrared Thermal imaging showed a maximum temperature of 45.3°C. This is well within the permissible limits for any transformer. But AI helped in stating the fact that even 45.3°C indicated abnormality in the Transformer. Thermal imaging helped in problem visualization. Refer to the thermal image given below:

The thermal image showed that the thermal profile of the left side of the transformer is in a relatively higher temperature range than the right side. It was a clear symptom of improper cooling. Cooling Oil might not be entering into the right-side radiator, or there could be blockages in the radiator. The suspected radiator valve was inspected. It was found that the valve was in a throttled condition. After the corrective action, the thermal image showed a balanced temperature gradient on both sides of the Transformer.The system was thermally balanced and safe. Refer to the thermal image given below:

(5) AI suggests Action prompts for Maintenance Options

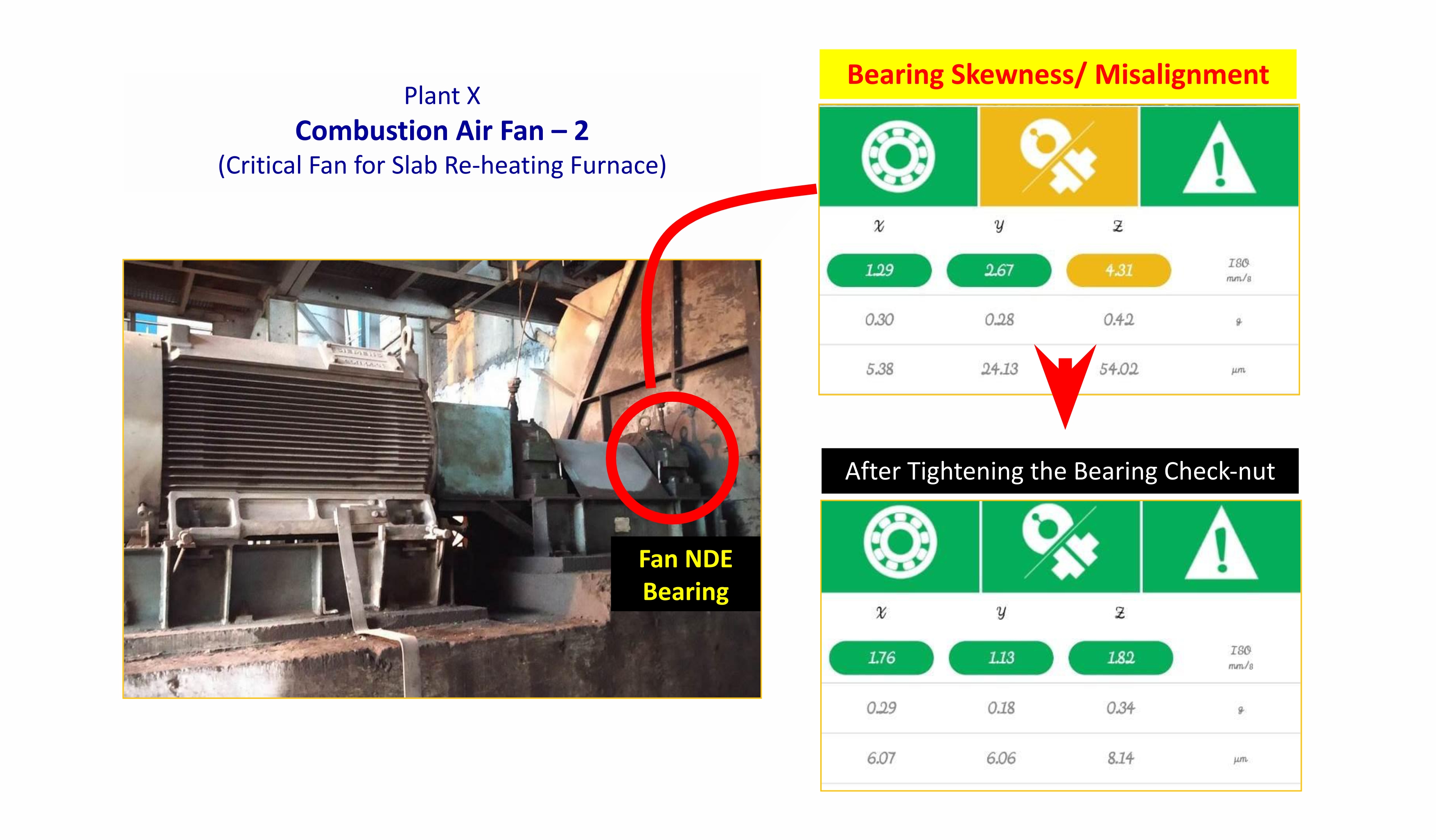

Rotor Unbalance, Coupling Misalignment, Base Looseness and stressed Bearings are the most common problems of any rotary machine. AI-based instruments do instantaneous Data Analytics and categorically identify the type of abnormality. IoT-based reports get generated showing the problems through pictorial representations. A solution becomes easy after problem visualization. The IoT-based report given below clearly shows that there is misalignment of bearing. After tightening of the bearing check nut, all parameters become a green zone.

(6) AI helps in Remote Asset Monitoring (RAM)

Steam Exhaust Fans were experiencing high bearing temperatures (> 93°C). IIoT-based wireless sensors were installed by the Condition Monitoring Team for cloud-based remote monitoring. Real-time Alarms of high temperature started to generate automatically, which were promptly attended to. It was a case of poor heat dissipation at bearing points. As a precautionary measure, a cooling air system was provided to all the heating bearings. The problem got resolved, though temporarily, but surprise failures were avoided.

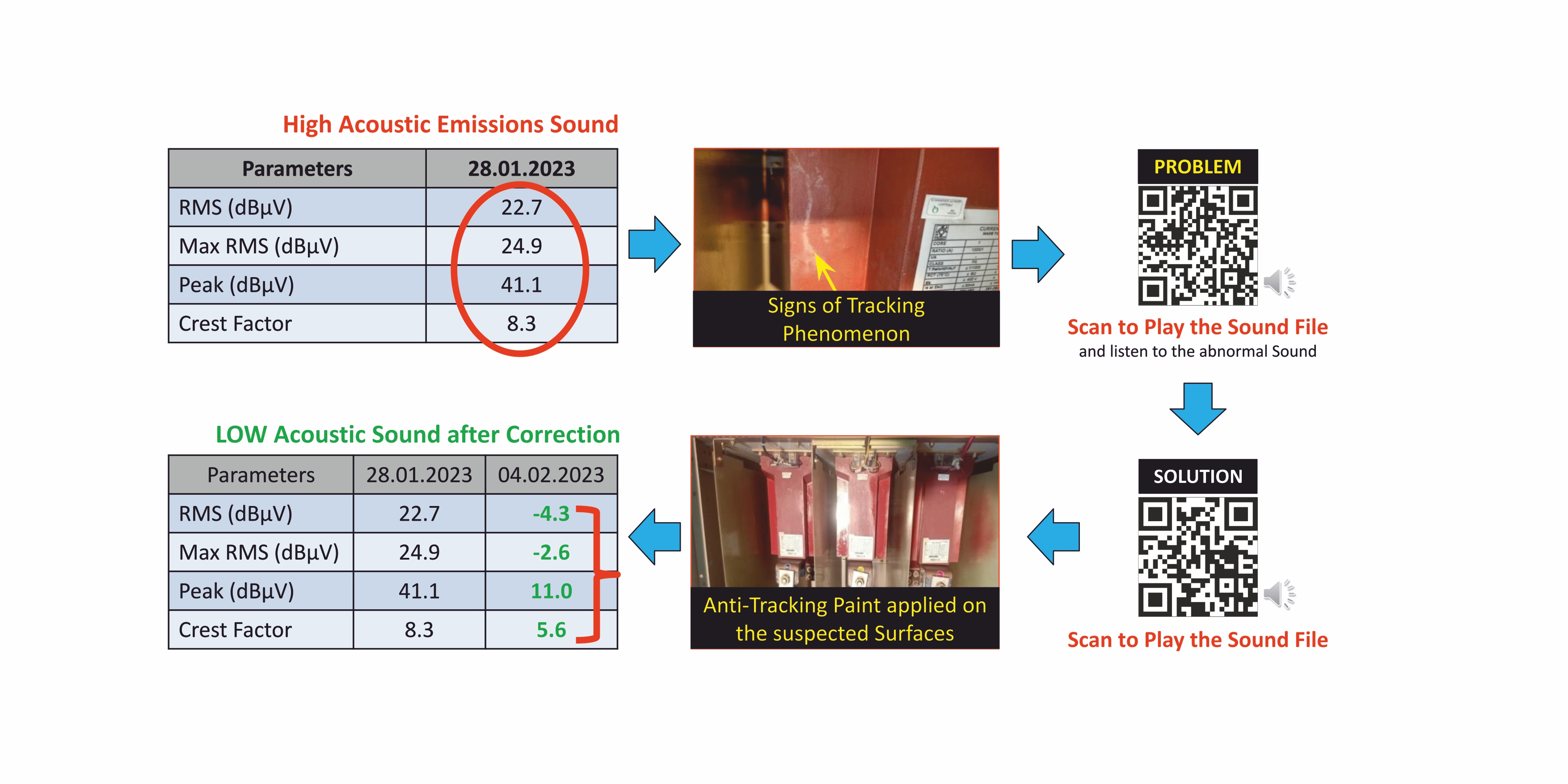

(7) AI converting Data to the level of Human Sense Organs

Partial discharge phenomena from Electrical Systems (Transformers and Electrical Panels) could be heard by using AI-based instruments. The instrument records the ultrasound and converts it into the audible range for human ears. The AI feature creates the sound files. These files give an instant analysis of the health of Electrical Systems. Before and after sound files can be generated for analysis, confirmation, and future reference.

Conclusion

DAD, MOM, and KID form the skeletal system for the AI architecture. They are interrelated and get accomplished in totality. They cannot work in silos because relevant data, the right Analysis, and prompt corrective actions are the prime steps of AI architecture. All the above case studies clearly highlight the benefits of Industry 4.0 Solution Options in the reliability and maintenance of industrial machines. Almost every industry is investing in AI-based initiatives with a focus on making the operations easy, profitable, and sustainable. But it needs caution. Just buying AI Technology will not help much unless and until it is user-friendly and application-worthy.

For example, installing only one type of online sensor for multiple parameters on different types of machines will not yield any positive result. Similarly, configuring random threshold alarm limits without taking into account the physical modelling of the acting forces and the environmental conditions will be of no gain. Too many Alarms in real time lose the importance of being considered by maintenance teams for any action. So, Alarms must be tuned and prioritized over a period of time. AI-enabled Sensors have a considerable cost. Cost-benefit analysis must be done. Prioritization of assets (machines) must be done based on their criticality within Production, Safety and Approach for Inspection.

The amalgamation of AI and Engineering has become a necessity for every industry that is trying to maximize the benefits and attain Business Sustainability. The combination of AI and Engineering has redefined the science of Condition Monitoring and Data Analysis, making the collection of machine-critical operational data, its processing and analytics, problem visualization, and action prompts fast and accurate. This transformation is essential for achieving business excellence through plant reliability and reaching sustainability goals.