Action towards Net Zero: An initiative by Oil & Gas Industry

The Government of India has articulated the concerns of developing countries at the 26th session of the

Conference of the Parties (COP26) to

the United Nations Framework Convention on Climate Change (UNFCCC) held in Glasgow in Nov 2021, United

Kingdom.

Further, India presented the following five nectar elements (Panchamrit) of India's climate action:

- Reach 500GWNon-fossil energy capacity by 2030

- 50 per cent of its energy requirements from renewable energy by 2030

- Reduction of total projected carbon emissions by one billion tonnes from now to 2030

- Reduction of the carbon intensity of the economy by 45 per cent by 2030, over 2005 levels

- Achieving the target of net zero emissions by 2070

India is the 3rd largest finished lubricant market in the world behind the US & China, with a total demand of ~3 million tonnes spread across Automotive, Industrial and Process Industries. Lubricants are blended from Base Oil produced from Crude Oil by the fractional distillation process. While India imports 85%+ of its Crude Oil requirements, we also import 75%+ of our Base Oil requirements. Rosefield estimates India spends more than $1.2 bn foreign exchange alone on Base Oil imports

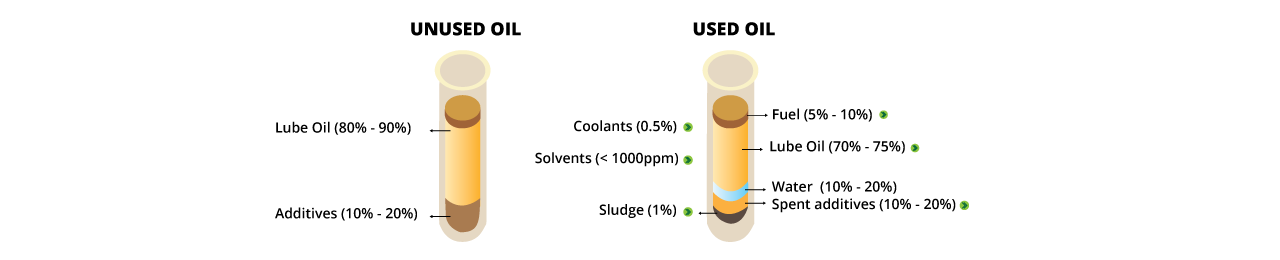

Depending on the formulation, Fresh Lubricants consist of 80-90% base oil and 10-20% additives. By their extreme operating conditions, Used Lube Oils contain base oil, degraded additives, metallic debris, oxidation products and carbon soot. Used Oils are thus highly contaminated Lube Oils. They are classified as Hazardous Waste per Part A of Schedule V of the Hazardous and Other Wastes (Management, Handling and Transboundary Movement) Rules, 2016

Used Oils are inherently recyclable, i.e. manufacturing processes that reproduce Base Oil from Used Oil exist. Such regenerated base oil is called Re-refined Base Oil (RRBO), while the Base Oil distilled from Crude Oil is called Virgin Base Oil (VBO).

Used Oils have higher levels of metals and PAHs than fresh oils, which lead to long-term risks including carcinogenicity. Improper disposal of Used Oils is a significant source of possible entry into the water system. Oil concentrations as low as one ppm can contaminate up to 1 million litres of drinking water with harmful impacts, including toxic contamination, destruction of food resources and habitats and impaired reproductive capability.

However, due to a lack of awareness and poor controls, the harmful Used Oils are either burnt in the open or in furnaces or indiscriminately disposed of, causing severe threats to human health and the environment. This results in serious environmental issues due to toxic air emissions and discharges of hazardous solid waste. Uncontrolled burning of Used Oils leads to emissions of metals and polycyclic aromatic hydrocarbons (PAHs), adsorbed by air-borne particulate matter and gets deposited in soil and water.

India’s unorganised Used Oil Collection

But the good news is that Used Oil can be recycled responsibly in various ways -

- Reconditioned on-site involves cleaning the Used Oil of contaminants before reusing it to extend its lifespan.

- Sent to a petroleum refinery and introduced into refinery production processes as a feedstock.

- Re-refined oil is used as an RRBO for fresh lubricating oil by processing old oil to eliminate contaminants (re-refining greatly improves the life of the oil resource).

- Processed and burned as fuel to generate heat or to power industrial operation.

As mentioned earlier, the last option is the least preferred because it only allows for one reuse of the oil and raises several environmental and health concerns due to the uncontrolled release of hazardous emissions. As per the US Environmental Protection Agency (EPA), re-refining Used Oil is the preferred form of recycling because it closes the recycling loop by reusing the oil to make the same product as when it started, using less energy and less Virgin Oil.

It is pertinent to note that 70 litres of RRBO is produced from 100 litres of Used Oil (70% process efficiency), whereas 70 litres of VBO is obtained by distilling 7000 litres of Crude Oil (as per the "cut" from fractional distillation process). Some studies also show that the energy required to manufacture RRBO from Used Oil is only 1/3rd of the energy needed to refine Crude Oil to produce VBO.

On the global stage, we are currently witnessing increased demand for RRBO and a greater focus on the re-refining industry due to environmental concerns.

Many Western countries have implemented policies such as providing tax benefits, setting a strict regulatory environment to ensure proper collection of Used Oil, improving consumer confidence in re-refined products and launching awareness campaigns to increase the adoption of re-refining as a preferred disposal method for managing used lubricants.

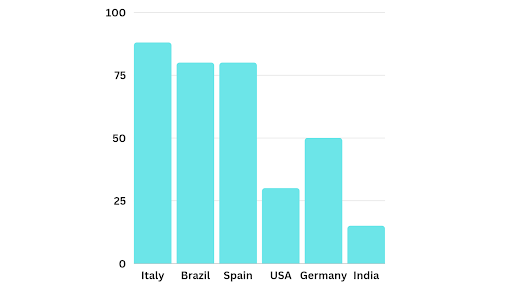

Re-refining Used Oil is supported and promoted in some European countries, especially those implementing Extended Producer's Responsibility (EPR) schemes for the Used Oil sector. For instance, Greece, Italy and Spain have achieved 80-98% re-refining rates for their used oil collection. RRBO from Used Oil currently accounts for nearly 13% of Europe's total Base Oil demand, and this share will only increase.

Re-Refined Base Stocks as a Percentage of Used Oil Collected

For a country like India, besides the environmental and sustainability benefits, RRBO can also reduce our import dependence while bringing in much-needed investments, and technological innovations & contribute to Make In India by creating jobs in the Oil & Gas Sector.

Thus, in India, RRBO becomes a compelling use case for moving to Net Zero in the Oil industry because Base Oil is infinitely recyclable!

Re-refining or regeneration of Used Oil into a Base Oil can go on for an infinite number of times thus significantly reducing our dependence on Virgin Base Oil, reducing Co2e drastically and protecting our natural resources and environment for future generations.

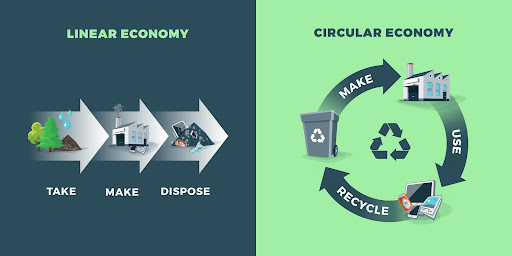

This concept is commonly referred to as “Circular Economy”, where the focus is to Reduce, Reuse and Recycle the waste. Repairs also increase the product life cycle and reduce usage of virgin natural resources. In addition, a Circular Economy also emphasises restoring natural systems while creating conditions for supporting regeneration.

On the contrary, Linear Economy is the traditional model where raw materials are collected and transformed into products that consumers use until discarding them as waste, with no concern for their ecological footprint and consequences.

The government in India has taken proper steps to move towards a Circular Economy by introducing a draft notification of EPR in Used Oil which mandates the collection and re-refining of Used Oil by Used Oil generators, collectors, recyclers, refiners and manufacturers.

This will ensure that we -

- Extract much lesser fossil fuels from the earth.

- Expend much less energy in extracting whatever we need to Send less toxic gases or solid/liquid waste into the air, water streams and landfills, thus reducing CO2e and taking a firm step towards achieving Net Zero.

The EPR objectives for waste oil recycling for producers and the relevant requirements, commencing in 2024–2025, are discussed in the drafting notification of EPR in Used Oil. It is mentioned that the recycling target is 10 percent for the base year, and it will steadily rise by 10 percent yearly until 2029. The objective will then be established based on the annual volume of lubricating oil sold or imported. Every producer, collection agent, recycler, and Used Oil importer must register on the platform according to the draft notification. This will assist India's Used Oil collection in moving from an unorganised, opaque sector to a formal, organised one.